ITIL Tutorial – Incident & amp Problem Management | The BEST Step-By-Step Guide

Last updated on 24th Aug 2022, Blog, Tutorials

Introduction

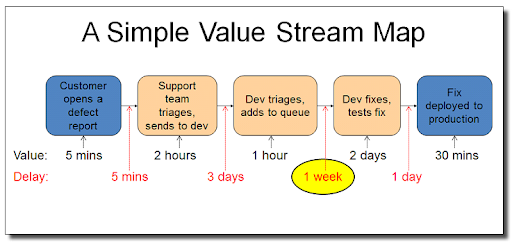

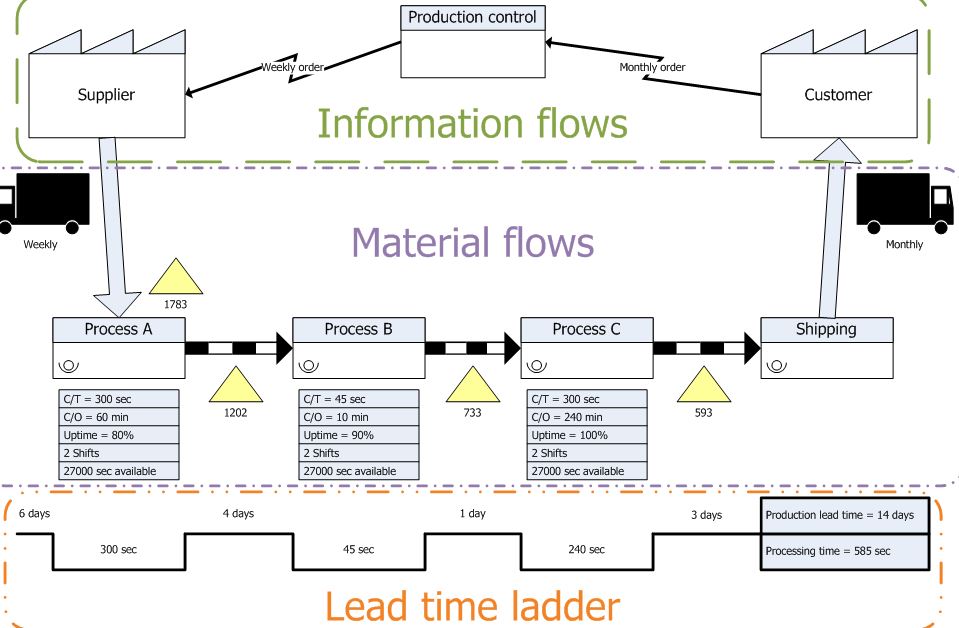

Value stream mapping could be a technique used to analyze the flow of knowledge, people, and materials needed to bring a product or service to a shopper. worth stream mapping could be a thought that originated in Lean producing methodologies. A typical method can comprise a series of steps and activities.These are classified as “value-adding,” that is, factors that add worth to the client and “non-value adding”, that is, factors that don’t add worth to the client. Worth stream mapping could be a key tool to spot and eliminate method waste to extend potency, throughput, and effectiveness.Note that simply being classified as “waste” doesn’t mean the step or method is mindless. It’s vital to know that ‘waste’ isn’t adding worth to the client and therefore ought to be reduced or avoided.

Value Stream Mapping – Stages:

Value stream mapping involves making visual maps of the method, referred to as worth Stream Maps. worth Stream Mapping progresses within the following stages:

Step 1: begin by distinctive the merchandise or service to be analyzed and therefore the worth being created by this method.

Step 2: produce a price stream map of this method by distinctive the steps, queues, delays, and knowledge flows.

Step 3: Review the map to search out delays, waste, and constraints. this may be done by reviewing the method and distinctive activities that may be classified as waste. Also, determine the constraints if any.

Step 4: produce a replacement worth stream map of the optimized state to be achieved within the future, by removing delays, waste, and constraints.

Step 5: Develop a roadmap to attain the longer term state.

Step 6: commit to return the method within the future to continually calibrate and optimize.

The steps concerned within the worth stream mapping method area unit as follows:

- Identify the beginning and finish purpose of the method

- Identify high-level steps, inventories, and queues

- Identify support teams and different flows

- Classify activities as worth adding and non-value adding

- Eliminate or minimize the non-value adding steps and optimize the method

Step 1:

Identify the place to begin the method, that is, the United Nations agency initiates it and also the termination, that’s, the United Nations agency gets the results of the method. As an example, the target is to urge Associate in Nursing approval of a story from the client. The worth stream mapping begins once you initiate the method of obtaining approval and ends once you and also the client agree on the story.

Step 2:

Identify the high-level steps, inventories, and queues through the method. Once these components are unit organized in a very sequence and showcased employing a flow sheet, they depict the first flow. during this example, the second step includes the subsequent activities:

- Select the story from backlog

- Meet the client

- Determine Acceptance Tests

Step 3:

Identify any supporting teams. These areas unit further to the worth stream flow sheet, in turn, they become the choice flows. during this case, on choosing the story from the merchandise backlog, you get the story cards, which require to be thought of for development within the iteration. If the client is unprosecutable, the choice flow would be to fulfill the client representatives, and the United Nations agency would act as a proxy client.

Step 4:

Classify every of the steps within the worth stream as either a worth adding or non-value adding activity. Please take a while to see the illustration of this method given below. During this case, there are unit delays in between the workflow that’s non-value adding activities. With these details, you’ll produce the worth stream of the system whereby the worth adding activities span for a hundred and forty minutes and non-value adding activities span for ninety minutes.Once this demarcation is completed, you’ll reason the potency of the method cycle victimization formula, total value-add time divided by total cycle time. The entire value-add time is a hundred and forty minutes and also the total cycle time, that is, the important adding time and non-value adding time is 230 minutes before improvement. Hence, the method potency is sixty one.

Step 5:

Either eliminate or minimize the non-value adding activities thereby optimizing the method. when optimizing, reason the potency of the method cycle victimization the formula, Total value-add time divided by Total cycle time. Post the improvement, the entire non-value add time is reduced by fifty five minutes, thereby the entire cycle time is reduced to 195 minutes. Hence, the method potency has improved to seventy two.

Value Stream Mapping – Example:

A subsidiary cluster of a publicly listed company produces a range of products utilized in the metal brazing, cutting, and fastening industries, Associate in Nursing, an array of gas-control instrumentation utilized in industrial, medical, and laboratory applications.As a part of its continuous improvement drive, the cluster wished to enhance the preparation of chrome-plated parts to assemble in its gas-pressure regulators. To attain this goal, they determined to use the technique of important stream mapping.

Solution:

The cluster performed a worth Stream Mapping analysis. The Worth Stream Mapping tool provides careful data on the flow of materials through a production method.It helped establish areas for improvement. The analysis concluded that to confirm a gradual flow of those parts through the assembly method, “supermarkets” had to be placed at numerous points on the assembly chain. Supermarkets are unit locations during which a regular quantity of inventory is kept. Once workers notice that the supermarket area unit is running low on materials, they stock them.

Outcome:

After reorganizing the assembly method, the cluster witnessed numerous enhancements. For the last eighteen months, there has been no shortage of parts for assembly into regulators. There was a seventy fifth reduction in WIP associated with the parts. This helped to attenuate inventory prices resulting in vital savings.

Following ar specific steps smaller firms will go for steel oneself against and deliver the goods price Stream Mapping (VSM).

Step 1: Gather Preliminary data

Before moving ahead with VSM, take care to collect the subsequent information:A history of your product combine from the previous year’s salesThe volume of sales for every product sold from the previous yearA list of your annual sales goals for future yearAny calculated assumptions from your sales and promoting strategy which will have an effect on your sales for future yearThis data is going to be helpful in making a history of your product combination, and therefore the volume of sales for every product can assist you apply Pareto’s 80-20 rule. In most cases, you may realize that twenty p.c of what you build represents eighty p.c of your business during a typical year.

For example: associate analysis for a corporation discovered that though the corporation offered quite a hundred completely different base products, solely 5 created up seventy two p.c of its overall business. During this case, company management at the start determined to limit the worth stream map to those 5 base products.However, once management checked out the sales goals for future year, 3 of the bottom products had targeted sales numbers that varied by five p.c, and 2 new products with massive projected sales volumes were planned for unleash. As a result, the analysis was changed so seven out of the entire range of base products amounted to eighty six p.c of the entire business. This was the ultimate analysis by that company management restricted the scope of its price stream mapping activity.

Step 2: produce a Product amount Routing Analysis

To create a product amount routing analysis, begin by listing all of your customers and therefore the product you build for every of them. take care to stay to the fundamentals once it involves your product. Don’t get over-involved with the varied choices which will be additional to your base product. List your base customary product that dissents in type, fit, and performance.Referencing your sales from the previous year, confirm the quantity for every product you created for your customers. Calculate the entire range of product created, showing the quantity of business generated from every client to know what your base demand was for the previous year. In, as an example, the entire is one hundred twenty five units.Determine the proportion of business that every product represents from your total range of units sold , and so establish the combination of products that represents around eighty p.c of your business. that blend are going to be what you wish to VSM, {which can|which can|which is able to} permit you to start thinking of what a model line will seem like in your operation. In different words, by price stream mapping the twenty p.c of the product that represents eighty p.c of your business, you’ll be able to establish and eliminate waste from these in-demand products so a majority of your business becomes additional economical.If you’re a piece-part manufacturer (PPM), you might ought to begin the method by creating an inventory of your customers. Use that list to calculate the entire range of finished piece elements you created from the previous year. Then confirm the proportion of business that every client represents from the quantity of elements you created.

Step 3: cluster Customers and kind Materials

The next step is to cluster your customers along by the business they represent. Figure three shows the entire range of finished piece elements together with the entire share of finished piece elements that every business represents.Sort out the amount of fabric sorts by every business and confirm what number elements account for every sort. The self-propelled vehicle (RV) business has metal elements and steel elements. (This situation is extremely common for a PPM.) during this case, merely confirm several|what percentage|What number} elements from the RV business are metal and the way many are steel. you are not ought to keep all the customer’s elements alone.The purpose of this exercise is to spot the product families you wish to map. several PPMs don’t recognize what their product families are, and if you are attempting to map each product family promptly during a HMLV surroundings, it’ll become too difficult.

Step 4: type Product Families by Build Sequence

The next step before VSM is to construct a method amount routing analysis to spot product families per an analogous build sequence. With this data, you may recognize specifically what you’re mapping through the flow of your operations.You have to grasp what elements or products flow through every work center and in what order. This helps you see that the product follows a constant routing sequence that logically be to cluster along. you may ought to look into drawings you employ to create the merchandise to make sure you perceive the routing of elements through the work centers.

Step 5: select One price Stream to start With

It is vital to grasp what product or piece elements comprise eighty % of your business and that product or piece elements of that eighty % add up to cluster along as a price stream (product family). begin by price stream mapping one price stream at a time to stay things straightforward. you will realize that though your analysis is examining eighty % of what you build, it’d be helpful to cluster along product or piece elements from different|the opposite} twenty % with other price streams.This could arise as a result of them following an equivalent build sequence and having similar kind, fit, and performance. Don’t be therefore militant in following the 80-20 rule that you simply don’t leave space for flexibility once opportunities arise that area unit logical to incorporate in your analysis

So, once selecting a price stream to begin with, think about the impact that price stream has on the business unit, such as:

- Highest % of sales volume.

- Market changes moving client demand.

- Profit margins of individual products.

- Warranty knowledge moving numerous product lines.

- Most enthusiasm from the corporate.

Step 6: produce AN Operations Flow Chart

Next, produce a flow chart of all the operations in your price stream. discuss with work order routings or the bill of materials for the merchandise price stream pro re nata to spot the steps and build a place to begin.

Step 7: Walk the workplace

When it’s time to map the merchandise family, the team must take a walk round the workplace. The temptation is to collect in an exceedingly meeting space viewing numbers you ran from your MRP system while not ever stepping foot onto your workplace. That’s a certain thanks to miss wasteful activity that the MRP system doesn’t report.Walk through the steps of your price stream wherever the work is being done. begin at the top of the method, operating your manner upstream to the start, to induce a customer-supplier perspective at every step. you’ll be ready to see any waste that’s occurring and whether or not it’s redundant or acceptable. Don’t rationalize waste and assume it’s happening solely owing to a replacement operator in coaching or a replacement product style, as you’ll miss distinctive opportunities for improvement.

Step 8: Collect the information

As you walk upstream through your price stream, you would possibly be speculative however within the world you’re reaching to collect all the information for every step! It will appear overwhelming for the team. simply keep in mind to stay your team moving, and don’t mire in “analysis dysfunction.” Knowledge assortment is very important, however not at the expense of taking months to induce something enforced.The first step is to discuss the routings you have obtained in your MRP system. Conduct time studies wherever applicable and review the results with the operators. If the operators and your team consider your results, then use this knowledge to fill within the gaps in your knowledge box for any method that’s missing knowledge. Operators are often the simplest supply for info once the information is inaccessible and you can’t conduct a scrutiny.Another option is to use knowledge from similar jobs. Referring back to your method amount routing analysis, you ought to be ready to determine different half numbers in your price stream that area units are similar. Run a report on a couple of comparable elements in your price stream to present you some knowledge to look at.

Step 9: Construct the worth Stream Mapping (VSM)

Metrics and Measurements. On a separate sheet of blank paper, begin constructing your price stream victimization symbols to point out what’s happening at every method.At every step, make certain to live with the suitable metrics as they apply to your method. This paints a decent image of this condition at every method, despite what your MRP system says or what others may tell you.Which metrics must you measure” That depends on your method. The purpose of VSM isn’t information collection; it’s to indicate to you wherever the worth is made and wherever the waste accumulates in your method.Flow of knowledge. A VSM ought to show not solely the flow of fabric, however conjointly the flow of knowledge. If you don’t shrewdly flow data to the workplace, you run the danger of processes anticipating instruction, taking a period of time. You furthermore might have an Associate in Nursing incomplete image of what you would like to enhance while not 1st knowing however the flow of knowledge can support your projected plan.For example, let’s say you’ve got an assembly that takes one hundred hours to complete. you choose that you simply wish to interrupt this into 2 stages into 2 totally different workcells. whereas it’d be to interrupt the total this fashion, however area unit you attend to recognize that components got to be routed to every workcell” however does one recognize once these components got to be routed? However, can the operators record their time? However, can drawings follow the work order (if you employ work orders)?When you begin mapping the flow of knowledge, you may discover why your lead-times area unit farewell.

Step 10: Summarize the info and acquire the large image

When you have known all the steps in your price stream and have stuffed altogether the info applicable to your VSM, it’s time to place it all at once. Figure eight demonstrates what a sample VSM ought to like once all the info has been collected. With this format, your team will stand back and appear at what the info is telling you concerning the flow through your method.Remember, the purpose isn’t to place along an inventive portrait of the flow through your price stream, however to use your VSM to visualize wherever the worth is being created and establish wherever wasteful activity happens. to assist you discover the waste, examine the method and raise yourself, “If the client were to steer through every step of this price stream together with his record in hand, would he be willing to acquire every step he sees””In addition, gazing at your VSM, take the list of kaizen opportunities you know during this method and start prioritizing them by level of impact Associate in Nursing improvement can build to the flow of your price stream. This can offer your team an Associate in Nursing organized set up of action for wherever to begin creating enhancements to your price stream.With your VSM in hand, you’re armed, ready, and well on your way thanks to eliminating waste and learning to visualize the total image. detain mind that learning to visualize isn’t solely the primary step in making a lean organization—it is 0.5 the battle.Benefits of a worth stream mapBy making a worth stream map, you’ll visualize how end-to-end operations work, track actual performance, and notice ways that to form your processes are even additional economical.Here area unit a number of the advantages useful stream mapping:

- Identify waste

- Identify bottlenecks

- Make processes economical

- Improve cross-functional collaboration

- Improve end-product quality

conclusion

Value stream map provides groups Associate in Nursing businesses an organization-wide perspective on lean project management, however the goal isn’t merely to spot this state of affairs.In addition to mapping this state, price stream mapping helps businesses visualize a perfect state of operations in project management, giving everybody within the organization a tangible goal to figure towards.

Are you looking training with Right Jobs?

Contact Us- Windows Azure Interview Questions and Answers

- Salesforce Architecture Tutorial

- Wrapper Class in Salesforce Tutorial

- salesforce lightning

Related Articles

Popular Courses

- VM Ware Training

11025 Learners - Microsoft Dynamics Training

12022 Learners - Siebel Training

11141 Learners

- What is Dimension Reduction? | Know the techniques

- Difference between Data Lake vs Data Warehouse: A Complete Guide For Beginners with Best Practices

- What is Dimension Reduction? | Know the techniques

- What does the Yield keyword do and How to use Yield in python ? [ OverView ]

- Agile Sprint Planning | Everything You Need to Know