SAP EWM Tutorial For Beginners | Ultimate Guide to Learn [UPDATED]

Last updated on 10th Aug 2022, Blog, Tutorials

What is SAP EWM?

SAP Extended Warehouse Management is known as SAP EWM. It supports the processing of inventory movement and is used to manage warehouse inventory. It helps the business to manage the movements of the goods inside the warehouse as well as the entering and departing activities of the warehouse. Incoming and exiting materials, completing customer orders, receiving and issuing goods, and distributing goods are a few of the crucial procedures that take place in the warehouse. Warehouse management is not necessary if a business is not keeping any products in storage. The storage of the items at the Warehouse and at their location is part of the inbound process, whilst the pickup of the goods is part of the outbound process.Using SAP EWM, a warehouse management system regulates the transportation of commodities. Effective management of the crucial processes and the delivery of the items is made possible by SAP EWM. Additionally, it provides resources for keeping an eye on warehouse operations. It is also possible to manage the warehouse’s additional features, including the generation of batch and serial numbers, vendor management inventory, value-added services, and resource optimization. Inventory management and SAP warehouse management are quite dissimilar. While warehouse management is concerned with the movement of items and keeping track of their physical locations, inventory management is concerned with the quantity of goods in a storage site whose location is unknown.

What distinguishes SAP EWM from SAP WM?

- The major activities of the warehouse may be managed with the help of sturdy and improved features in warehouse management. Warehouse management and SAP EWM are the same.

- For controlling the warehouse operations, it provides capabilities like picking, RF framework, put away, warehouse structure, and many other adaptable possibilities.

- In SAP EWM, new features can be generated, such as resources, activity areas, work centers, and labor management, which are not available in WM.

- For managing warehouse operations, a business might use SAP EWM as a reliable solution. Additionally, it supports each and every logistical and supply chain operation.

Characteristics of SAP EWM: Some of SAP EW’s key features include:

- SAP EWM can manage warehouse tasks like picking, posting of items, managing storage bins, and receiving of goods.

- It aids in reversing or rectifying the receipt of goods from the EWM to the ERP system, an incoming delivery division from the EWM to the ERP system, and issuing an alert for the updated data prior to receiving the goods from the EWM to the ERP system.

- Before being placed in separate storage sections, handling units containing a variety of items might be deconsolidated.

- Slotting for items and automatically optimising the layout of goods warehouses can be used to develop storage solutions.

- It enables us to carry out executable tasks, such as work packages, including warehouse-related chores that must be completed by warehouse employees as part of warehouse activities.

- We can manage and track vehicles and other transportation units, as well as movements and other yard tasks, from yard check-in to yard check-out.

- SAP Environmental Health & Safety EHS standards apply to the storage, handling, and transportation of hazardous materials as well.

- We can successfully manage our warehouse’s essential resource management tasks thanks to SAP EWM’s excellent labour time and resource planning capabilities.

- In SAP EWM, the warehouse cockpit can be used to graphically present warehouse important figures and to assess or monitor activity using predefined chart types.

- Cross-docking is the process of moving handling units between different distribution centers or warehouses to get them to their destination inside the facility.

SAP EWM Architecture:

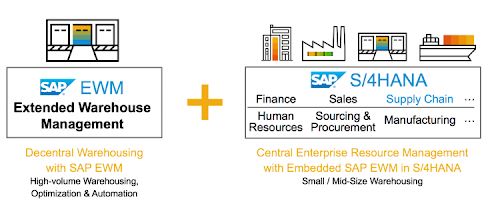

SAP EWM can be utilized in any warehouse system and is regarded as a standalone application. EWM’s main responsibilities include monitoring inventory down to the level of storage bins, selecting the appropriate storage location for incoming and exiting goods, and packing products for delivery to clients. Two variations of SAP EWM exist. One of them is decentralized, arrives in a distinct container, and requires an interface like Core Interface CIF for master data exchange between the EWM and the ERP. ECC and EWM are integrated into a single system with S/4 HANA, though, thus CIF is not necessary.

EWM Organization Structure:

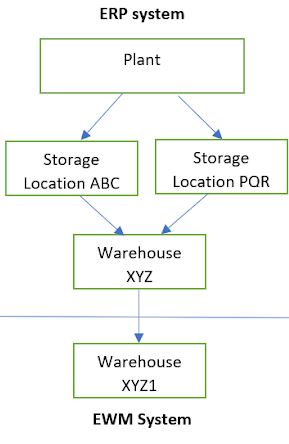

The plant and the storage location of that plant must be linked with the appropriate warehouse number, which will then be allocated to the EWM warehouse number, in order to activate the warehouse management in the ERP system. The structural components of the EWM warehouse that must be configured within the EWM system are listed below.

Storage type: The SAP EWM also has a storage type section. It alludes to the warehouse’s technological specifications, needed space, and storage area. Depending on how it will be used, a specific role should be specified for the storage type.

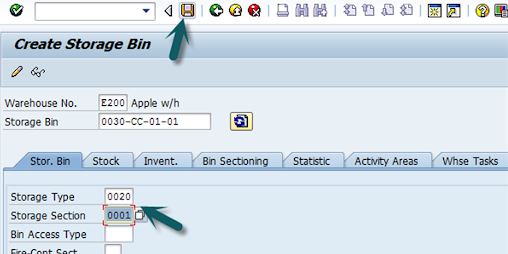

Storage section: Depending on its characteristics, the storage type is subsequently divided into storage sections. Additionally, it is mixed with other bins that share characteristics like being light, heavy, sluggish, or rapid. EWM’s storage portion can be exploited opportunistically.

Storage bins: These represent the precise place in the warehouse where a product may be stored and are the smallest addressable unit of space in the warehouse. As far as the Warehouse is concerned, it is distinctive. Every storage container has a certain type of container that is related to its characteristics.

Quant: This refers to a certain product’s stock or existence in the resource, storage container, and transit unit. The different quants are the several batches that make up a product.

Activity area: Activity areas are where warehouse tasks like picking, putting away, and physical inventory are completed. One or more storage containers are assigned to the activity area. The same storage container may be assigned to more than one activity area depending on the activity. The designated containers are arranged according to the activity sector for each activity. Depending on the storage bins’ assignment to a particular activity area, this enables the optimization of the order in which warehouse chores are performed.

Staging Areas: Material may be stored in the temporary storage space known as a staging area before loading or after unloading. A staging area designates a storage compartment of the “D” storage type. Determine whether the activity being performed in the staging area is incoming, outgoing, or both in order to set it up. The option of assigning a loading rule is also available. One or more bins, sometimes known as staging bays for this kind of storage, may be included in the storage area.

Door: For both arriving and exiting shipments, a warehouse door may be employed. The delivery updates the door from whence the shipment was sent. Vehicles and transport units drive up to the warehouse’s doors to load or unload cargo. The entrance could serve as a staging area or yard bin.

Work center: Packing, quality inspection, counting, VAS, deconsolidation, and other tasks are performed in a physical unit called the “work center” in a warehouse. Each work center will be given a specific warehouse number, storage type, and storage bin.

Supply chain unit: A physical or organizational unit employed in the logistical process for a certain business attribute, such as a shipping office or products receiving office, is referred to as a supply chain unit.

Documentation for SAP EWM Architecture:

Notification of inbound delivery: The Supplier’s Shipping Notification is saved in the Inbound Delivery Notification (IDN). It comprises all logistics data connected to the incoming delivery process and is automatically created with an incoming message; it was used as the reference document for establishing Inbound Delivery.

Inbound delivery (Warehouse Request): It contains all of the data required to initiate and monitor the whole inbound delivery process, which is automatically created upon the activation of the Inbound Delivery Notification.

Outbound Delivery Request: It contains all logistical data important to the outbound delivery process and is generated automatically by incoming communications. It serves as a reference document for the establishment of an outbound delivery order.

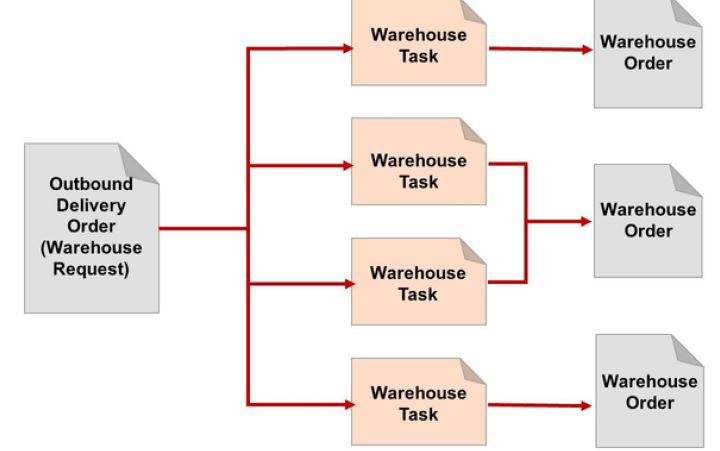

Outbound delivery order (warehouse request): It contains all of the information required to initiate and track the whole outbound delivery process and is generated automatically after the outbound delivery request is activated.

Posting Change: This is a document that contains all of the information required to complete the EWM posting change process. It occurs in the EWM once the transfer posting document is uploaded in the ERP.

Warehouse Request: This is a document that permits warehouse activities for a specific product to be processed, such as putaway, picking, stock transfer, posting change, and scrapping. The system generates the following types of warehouse requests Posting Change, outbound delivery, inbound delivery, internal stock transfer.

The following are the basic warehousing processes in the SAP EWM architecture:

Process of issuing outbound goods: The process begins with the generation of sales orders and outbound deliveries in ERP, which results in the creation of outbound delivery order documents in EWM via PPf action. This document contains additional EWM-relevant data specified by the service profiles associated with the outbound delivery document type and delivery category. It is the warehouse requisition document for the EWM goods distribution procedure. Warehouse tasks are formed from outbound delivery orders to control picking and other related activities such as packaging, loading, and staging.

Inbound goods receiving process: The inbound process begins with the creation of an inbound delivery in SAP ERP from an ASN or purchase order. The solution defines the SAP EWM architecture for specific characteristics, such as warehouse process type, and generates the ID within EWM using a post-processing framework. Goods will be placed in the storage bin or storage type by creating warehouse jobs in the EWM via incoming delivery.

Conclusion:

In this tutorial, we learnt about SAP EWM, how it differs from WM, the features of SAP EWM, the architecture of EWM, and so on. We hope this information was useful to you. If you are looking for other SAP-related subjects, please leave a comment in the comments below. We shall do so.

Are you looking training with Right Jobs?

Contact Us- Windows Azure Interview Questions and Answers

- Salesforce Architecture Tutorial

- Wrapper Class in Salesforce Tutorial

- salesforce lightning

Related Articles

Popular Courses

- VM Ware Training

11025 Learners - Microsoft Dynamics Training

12022 Learners - Siebel Training

11141 Learners

- What is Dimension Reduction? | Know the techniques

- Difference between Data Lake vs Data Warehouse: A Complete Guide For Beginners with Best Practices

- What is Dimension Reduction? | Know the techniques

- What does the Yield keyword do and How to use Yield in python ? [ OverView ]

- Agile Sprint Planning | Everything You Need to Know