- Understanding Agile Methodologies and Principles | A Complete Tutorial

- What is a Work Breakdown Structure (WBS)? | Learn Overview, Steps, Benefits

- Traditional Project Management Tutorial | A Comprehensive Guide

- Total Quality Management (TQM): Complete Guide [STEP-IN]

- Total Productive Maintenance Tutorial | Get an Overview

- Virtual Team Tutorial – Learn Origin, Definition and its Scope

- The Rule of Seven in Project Management – Tutorial

- Make or Buy Decision – A Derivative Tutorial for Beginners

- What is Halo Effect? | Learn More through Tutorial

- Balanced Score Card Tutorial | Learn with Definition & Examples

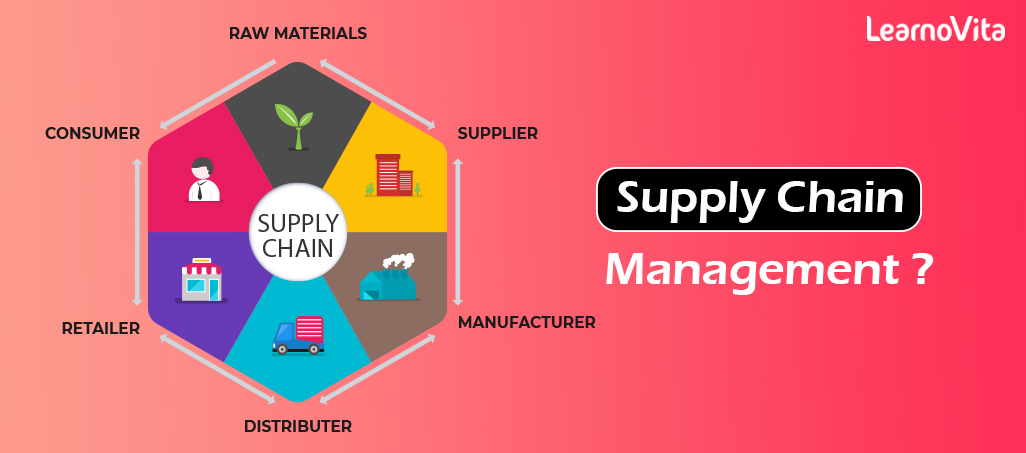

- What is Supply Chain Management? | Tutorial with Examples

- Succession Planning Tutorial | A Complete Guide with Definitions

- What is Structured Brainstorming? | Quickstart & Learn the Tutorial

- Stress Management Tutorial | A Comprehensive Guide for Beginners

- What is a Statement of Work? | Learn with Definition & Examples

- What is Stakeholder Management? – The Ultimate Guide for Beginners

- How to Create a Staffing Management Plan? | Learn from Tutorial

- What is Resource Leveling? | A Comprehensive Tutorial

- Requirements Collection Tutorial: Gather Project Needs

- What Is a RACI Chart? | Learn with Example & Definitions

- Quality Assurance vs Quality Control: Tutorial with Definitions & Differences

- Project Workforce Management Tutorial | A Definitive Guide

- Project Time Management Tutorial: Strategies, Tips & Tools

- Project Management Success Criteria Tutorial | Understand and Know More

- Identify Risk Categories in Project Management | A Comprehensive Tutorial

- Project Records Management Tutorial | Quickstart -MUST READ

- Project Quality Plan (PQP) Tutorial | Ultimate Guide to Learn [BEST & NEW]

- Project Portfolio Management | A Defined Tutorial for Beginners

- Goals of a Project Manager Tutorial | The Ultimate Guide

- Project Management Triangle Tutorial: What It Is and How to Use

- Project Management Tools Tutorial | Learn Tools & Techniques

- What is PMO (project management office)? | A Complete Tutorial from Scratch

- Project Management Lessons | Learn in 1 Day [ STEP-IN ]

- What is a Project Kickoff Meeting? | Learn Now – A Definitve Tutorial

- Project Cost Management Tutorial | Steps, Basics, and Benefits

- Types of Contracts in Project Management | Learn with Examples

- Project Activity Diagram | Ultimate Guide to Learn [BEST & NEW]

- What is Project Procurement Management? | Tutorial Explained

- Procurement Documents Tutorial | The Ultimate Guide

- Process-Based Project Management Tutorial: A Beginner’s Guide

- What Is PRINCE2 Project Management? | A Definitive Tutorial for Beginners

- Effective Presentation Skills – Learn More through Tutorial

- Powerful Leadership Skills Tutorial | The Ultimate Guide

- PERT Estimation Technique Tutorial | Explained with Examples

- Pareto Chart Tool Tutorial | Learn Analysis, Diagram

- Organizational Structure Tutorial: Definition and Types

- Negotiation Skills for Project Management | Learn from the Basics

- Monte Carlo Analysis in Project Management Tutorial | A Perfect Guide to Refer

- Effective Management Styles Tutorial | The Ultimate Guide

- Management by Objectives (MBO) Tutorial | Overview, Steps, Benefits

- Leads, Lags & Float – Understand the Difference through Tutorial

- What is Knowledge Management? – Tutorial Explained

- What is Just-in-Time Manufacturing (JIT)? | Know More through Tutorial

- Gantt Chart Tool Tutorial: The Ultimate Guide

- Extreme Project Management Tutorial – Methodology & Examples

- Introduction for Event Chain Methodology Tutorial | Guide For Beginners

- Enterprise Resource Planning (ERP) | A Complete Tutorial for Beginners

- What Is Design of Experiments (DOE)? | Learn Now – A Definitve Tutorial

- Decision Making Tutorial – Know about Meaning, Nature, Characteristics

- Critical Path Method Tutorial | How to use CPM for project management

- What is Critical Chain Project Management? | A Complete Tutorial

- What is Conflict Management? | Learn the Definition, styles, strategies through Tutorial

- Effective Communication Skills Tutorial – Definitions and Examples

- Communication Models Tutorial – Project Management

- Methods of Communication Tutorial | A Complete Learning Path

- Communication Management Tutorial | Know more about Plans & Process

- What are Communication Channels? | Learn Now Tutorial

- Communication Blocker Tutorial | Explained with Examples

- Cause and Effect Diagrams Tutorial | The Ultimate Guide

- What is Benchmarking? | Technical & Competitive Tutorial

- Seven Processes of Prince2 Tutorial | Everything you Need to Know

- Design Thinking Tutorial – Quick Guide For Beginners

- What is Performance Testing | A Complete Testing Guide With Real-Time Examples Tutorial

- What is Confluence? : Tutorial For Beginners | A Complete Guide

- Lean Six Sigma Tutorial

- Agile Scrum Tutorial

- PMI-RMP Plan Risk Management Tutorial

- Designing the Blueprint Delivery Tutorial

- What is Confluence? : Tutorial For Beginners | A Complete Guide

- Program Benefits Management Tutorial

- Continuous Improvement – Agile Value Stream Mapping

- Program Organization Tutorial

- Risk and Issue Management Tutorial

- Project Integration Management Tutorial

- Planning and Control Tutorial

- Program Management Principles Tutorial

- program strategy Alignment Tutorial

- PMP Tutorial

- Program Governance Tutorial

- Program Life Cycle Management Tutorial

- PMP Exam Preparation Tutorial

- PMI-PgMP Tutorial

- Agile Methodologies and Frameworks- Kanban and Lean Management Tutorial

- JIRA Tutorial

- Primavera P6 Tutorial

- Understanding Agile Methodologies and Principles | A Complete Tutorial

- What is a Work Breakdown Structure (WBS)? | Learn Overview, Steps, Benefits

- Traditional Project Management Tutorial | A Comprehensive Guide

- Total Quality Management (TQM): Complete Guide [STEP-IN]

- Total Productive Maintenance Tutorial | Get an Overview

- Virtual Team Tutorial – Learn Origin, Definition and its Scope

- The Rule of Seven in Project Management – Tutorial

- Make or Buy Decision – A Derivative Tutorial for Beginners

- What is Halo Effect? | Learn More through Tutorial

- Balanced Score Card Tutorial | Learn with Definition & Examples

- What is Supply Chain Management? | Tutorial with Examples

- Succession Planning Tutorial | A Complete Guide with Definitions

- What is Structured Brainstorming? | Quickstart & Learn the Tutorial

- Stress Management Tutorial | A Comprehensive Guide for Beginners

- What is a Statement of Work? | Learn with Definition & Examples

- What is Stakeholder Management? – The Ultimate Guide for Beginners

- How to Create a Staffing Management Plan? | Learn from Tutorial

- What is Resource Leveling? | A Comprehensive Tutorial

- Requirements Collection Tutorial: Gather Project Needs

- What Is a RACI Chart? | Learn with Example & Definitions

- Quality Assurance vs Quality Control: Tutorial with Definitions & Differences

- Project Workforce Management Tutorial | A Definitive Guide

- Project Time Management Tutorial: Strategies, Tips & Tools

- Project Management Success Criteria Tutorial | Understand and Know More

- Identify Risk Categories in Project Management | A Comprehensive Tutorial

- Project Records Management Tutorial | Quickstart -MUST READ

- Project Quality Plan (PQP) Tutorial | Ultimate Guide to Learn [BEST & NEW]

- Project Portfolio Management | A Defined Tutorial for Beginners

- Goals of a Project Manager Tutorial | The Ultimate Guide

- Project Management Triangle Tutorial: What It Is and How to Use

- Project Management Tools Tutorial | Learn Tools & Techniques

- What is PMO (project management office)? | A Complete Tutorial from Scratch

- Project Management Lessons | Learn in 1 Day [ STEP-IN ]

- What is a Project Kickoff Meeting? | Learn Now – A Definitve Tutorial

- Project Cost Management Tutorial | Steps, Basics, and Benefits

- Types of Contracts in Project Management | Learn with Examples

- Project Activity Diagram | Ultimate Guide to Learn [BEST & NEW]

- What is Project Procurement Management? | Tutorial Explained

- Procurement Documents Tutorial | The Ultimate Guide

- Process-Based Project Management Tutorial: A Beginner’s Guide

- What Is PRINCE2 Project Management? | A Definitive Tutorial for Beginners

- Effective Presentation Skills – Learn More through Tutorial

- Powerful Leadership Skills Tutorial | The Ultimate Guide

- PERT Estimation Technique Tutorial | Explained with Examples

- Pareto Chart Tool Tutorial | Learn Analysis, Diagram

- Organizational Structure Tutorial: Definition and Types

- Negotiation Skills for Project Management | Learn from the Basics

- Monte Carlo Analysis in Project Management Tutorial | A Perfect Guide to Refer

- Effective Management Styles Tutorial | The Ultimate Guide

- Management by Objectives (MBO) Tutorial | Overview, Steps, Benefits

- Leads, Lags & Float – Understand the Difference through Tutorial

- What is Knowledge Management? – Tutorial Explained

- What is Just-in-Time Manufacturing (JIT)? | Know More through Tutorial

- Gantt Chart Tool Tutorial: The Ultimate Guide

- Extreme Project Management Tutorial – Methodology & Examples

- Introduction for Event Chain Methodology Tutorial | Guide For Beginners

- Enterprise Resource Planning (ERP) | A Complete Tutorial for Beginners

- What Is Design of Experiments (DOE)? | Learn Now – A Definitve Tutorial

- Decision Making Tutorial – Know about Meaning, Nature, Characteristics

- Critical Path Method Tutorial | How to use CPM for project management

- What is Critical Chain Project Management? | A Complete Tutorial

- What is Conflict Management? | Learn the Definition, styles, strategies through Tutorial

- Effective Communication Skills Tutorial – Definitions and Examples

- Communication Models Tutorial – Project Management

- Methods of Communication Tutorial | A Complete Learning Path

- Communication Management Tutorial | Know more about Plans & Process

- What are Communication Channels? | Learn Now Tutorial

- Communication Blocker Tutorial | Explained with Examples

- Cause and Effect Diagrams Tutorial | The Ultimate Guide

- What is Benchmarking? | Technical & Competitive Tutorial

- Seven Processes of Prince2 Tutorial | Everything you Need to Know

- Design Thinking Tutorial – Quick Guide For Beginners

- What is Performance Testing | A Complete Testing Guide With Real-Time Examples Tutorial

- What is Confluence? : Tutorial For Beginners | A Complete Guide

- Lean Six Sigma Tutorial

- Agile Scrum Tutorial

- PMI-RMP Plan Risk Management Tutorial

- Designing the Blueprint Delivery Tutorial

- What is Confluence? : Tutorial For Beginners | A Complete Guide

- Program Benefits Management Tutorial

- Continuous Improvement – Agile Value Stream Mapping

- Program Organization Tutorial

- Risk and Issue Management Tutorial

- Project Integration Management Tutorial

- Planning and Control Tutorial

- Program Management Principles Tutorial

- program strategy Alignment Tutorial

- PMP Tutorial

- Program Governance Tutorial

- Program Life Cycle Management Tutorial

- PMP Exam Preparation Tutorial

- PMI-PgMP Tutorial

- Agile Methodologies and Frameworks- Kanban and Lean Management Tutorial

- JIRA Tutorial

- Primavera P6 Tutorial

What is Supply Chain Management? | Tutorial with Examples

Last updated on 24th Aug 2022, Blog, Project Management, Tutorials

Introduction :-

Store network the executives may be characterized because the administration of stream of things and administrations, that starts from the start of things and finishes with the item’s utilization toward the end-client. This is often a compact timely tutorial exercise that clarifies the systems applied within the quickly developing space of offer Chain Management in AN association.In AN association, forward AN item is created utilizing unrefined elements from completely different suppliers and within the event that this stuff is offered to purchasers, a store network is created. Contingent upon the dimensions of the association and therefore the amount of things that are created, a listing network could be knotty or basic.

Store network Management alludes to the administration of AN interconnected organization of organizations related to a definitive conveyance of labor and merchandise to purchasers.It involves the capability and transport of unrefined elements, the course of stock and therefore the capability and transportation of the last merchandise from the place of collection to the mark of utilization.The expression “store network the board” was initially instituted by Keith King Oliver in 1982. King Oliver characterized in 1982 the availability Chain plan as follows: – “Store network the executives (SCM) is that the commonest manner of transcription, ending, and dominant the tasks of the assembly network with the rationale to satisfy shopper stipulations as proficiently as may very be expected.

Production network the board traverses all development and capability of unrefined elements, work-in-process stock, and completed merchandise from basis to point-of-utilization”. From that time forward, many Chain Book writers have fostered their own definitions.They accepted that the term was snappy and therefore the I2M abbreviation would be typically welcome, but everything was modified throughout a key directive panel meeting with Dutch hardware monster Philips. At the gathering, he and his cluster discovered that their snappy expression wasn’t too appealing, and King Oliver was tested by one among the client’s chiefs: man. Van t Hoff. King Oliver processed man. Van t’Hoff what he understood by I2M: “We’re discussing the administration of a series of offer adore it were a solitary component,” Mr. King Oliver answered, ―not a gathering of dissimilar capacities.

“why don’t you decide that?” man. Van t’Hoff same. “Call it what?” man. King Oliver inquired. that within the wake of knowing the story, he wasn’t entirely bound forward; it absolutely was Keith King Oliver or man. Van t Hoff, United Nations agency, authored the term.In any case, as King Oliver fostered the thought preceding the gathering and concerned it initially getting into the open throughout the money Times interview, offers credit to Oliver’s story to be the Ring of Truth. Even so, the thought of a listing network in administration was crucial well before, within the middle twentieth century, significantly with the assembly of the consecutive construction system.The qualities of this point of inventory network the executives incorporate the necessity for large scope changes, re-designing, scaling back driven by value decrease programs, and much reaching regard for Japanese administration rehearses.

What is the inventory network of the executives?

Store network the board is that the treatment of the entire presentation stream of an honest or administration – starting from the crude components the complete thanks to conveyancing the tip result to the patron. a corporation makes a corporation of suppliers (“joins” within the chain) that move the item on from the suppliers of unrefined elements to those associations that manage purchasers.

How really will the store network work?

As per CIO, there are 5 components of customary store network the board frameworks:

Arranging:Set up associate degree to cope with all assets expected to satisfy consumer want for an organization’s item or administration. Whenever the assembly network is ordered out, measurements to determine whether or not the shop network is skillful, viable, conveys price to purchasers and meets organization objectives.

Obtaining:Decide suppliers to provide the labor and merchandise expected to form the item. Then, at that time, lay out cycles to screen and manage supplier connections. Key cycles include: requesting, getting, overseeing stock and approving supplier installments.

Producing:Place along the exercises expected to acknowledge unrefined elements, build the item, check for quality, bundle for transportation and timetable for conveyance.

Conveyance and Logistics:Coordinate consumer orders, set up conveyances, dispatch masses, receipt purchasers and acquire installments.

Returning:Build a corporation or interaction to reclaim blemished, overabundance or undesirable things.

Why is the production network the board significant?

Powerful inventory networks the board frameworks limit value, burn through and time within the creation cycle. The business normal has been a while not a flash to spare store network wherever retail deals consequently signal recharging requests to producers. Retail retirements will then be restocked nearly as quickly as items are sold-out. One technique for facilitating development of this cycle is to interrupt down the data from production network accomplices to examine wherever any enhancements are often created.

By examining help data, the CIO.com post acknowledges 3 things wherever triple-crown store network the executives builds price to the assembly network cycle:

Recognizing doable problems. At the purpose once a consumer arranges additional items than the producer will convey, the client will grumble of helpless help. Through data examination, manufacturers may need the choice to expect the dearth before the client is pessimistic.

Enhancing value increasingly. Occasional things have a restricted time span of usability. Toward the end of the amount, these things are usually rejected or sold-out at profound limits. Carriers, inns et al with temporary “items’ ‘ usually modify prices powerfully to satisfy want. By utilizing perceptive programming, comparative deciding procedures will develop edges, in any event, for laborious merchandise.

Logical programming apparatuses facilitate powerfully distributed assets and timetables, add read of the business gauge, real orders and bonded conveyance of natural substances. manufacturers will affirm associate degree item conveyance date once the request is placed – altogether modification mistakenly took care of requests.

Key components of powerful inventory network the board :-

The production network is the clearest “face” of the business for purchasers and shoppers. the higher associate degree additional compelling an organization’s store network the executives is, the higher it safeguards its business infamy and long-standing time supportability.

IDC’s Simon Ellis within the Path to a Thinking offer Chain characterizes what’s production network the board by recognizing the 5 “Cs” of the powerful production network the executives of things to come:

Associated:Being able to get unstructured data from web-based media, organized data from the web of Things (IoT) and additional customary informational collections accessible through typical ERP and B2B combine apparatuses.

Cooperative:Rising joint effort with suppliers increasingly implies the use of cloud-based business organizations to empower multi-endeavor coordinated effort and commitment.

Digital mindful:The assembly network ought to solidify its frameworks and safeguard them from digital interruptions and hacks, that ought to be a trial wide concern.

Intellectually empowered:The AI stage turns into the advanced inventory network’s tower by ordering, designing and leading decisions and activities across the chain. The bulk of the shop network is mechanized and self-learning.

Exhaustive:Analytics skills ought to be scaled with data ceaselessly. Bits of information are in depth and fast. Dormancy is inadmissible within the inventory network of things to come back. Several stock chains have started this cycle, with cooperation in cloud-based business networks at associate degree exceeding high and vital endeavors currently to bolster examination capacities.

Advancement of production network the executives :-

While the previous stock chains were focused around the accessibility, development and value of actual resources, the current inventory chains are regarding the administration of knowledge, administrations and things packaged into arrangements.Present day inventory network the executives frameworks are regarding significantly quite precisely wherever and once. Inventory networks the board influences item and administration quality, conveyance, costs, consumer expertise and eventually, benefit.

As late as 2017, a traditional inventory network ought to multiple times an even bigger variety of knowledge than solely 5 years sooner. nevertheless, underneath a fourth of this data is being compound. That suggests the price of basic, time-delicate data – like information regarding climate, surprising work deficiencies, political distress and microbursts wanted – are often lost.Present day offer chains exploit huge measures of knowledge made by the chain cycle and are organized by logical specialists and knowledge researchers. Future production network pioneers and also the Enterprise Resource designing (ERP) frameworks they manage can in all probability zero in on upgrading the availability of this data – dissecting it ceaselessly with insignificant immobility.

Production network substance :-

With IBM Services, you’ll advance your inventory network processes into wise work processes, to hit new degrees of responsiveness and development.Challenge siloed cycles to uncover efficiencies, empower your teams to execute and convey, and utilize arising innovations like AI and blockchain to open doors in every progression of the value chain – from interest desperate to prepare organization and satisfaction.Worldwide store network pioneers are compelled to usually value customary approaches to operating, wherever the most effective danger in exploring interruptions is acting with the previous principle. IBM inventory network substance administrations will fortify inventory network the board, aiding shoppers with building robust, sylphlike and rectifiable stockpile chains for what’s to return. Our results driven methodology, market-driving advancements and coordination capacities assist you with developing your inventory network work processes, hyper automate direction, develop productivity and have interaction with your kin.

1. Request composing :

The SCM cycle begins with finding out what things shoppers would like. This stage includes the start phases of store network composing, usually thought to be one in all the 2 overall categories of SCM aboard store network execution. Inventory network composing begins with request composing, associate degree interaction for event chronicled info, as an example, past deals, and applying investigation and factual displaying to electrify a gauge or interest arrange that the reach cluster and useful offices for example, collection and advertising will decide on. The conjecture decides the types and amounts of things to be created.

Getting the conjecture right is basic for keeping aloof from outrageous problems, as an example, the bullwhip impact, within which very little variances in retail request square measure amplified more up the assembly network, prompting extreme deficiencies or excesses of stock.A few organizations perform request composing as a feature of a formalized interaction known as deals and tasks composing (S & OP), that envelops associate degree reiterative course of data gathering, spoken language, accommodating of interest plans with creation plans, and also the board endorsement.A few organizations bear in mind S & OP for an additional intensive cycle known as coordinated business composing (IBP) that joins different offices’ arrangements in a very solitary company wide arrangement.

2.Creation composing :

In the following vital stage, creation composing, the organization makes sure concerning the particulars of wherever and the way the things needed within the interest arrange are created.(Creation composing is likewise used in numerous enterprises, like factory farms and oil and gas.) associate degree all the additional adjusted selection known as timely arrangement and booking (APS; nevertheless, APO for streamlining) appearance to boost the assets that move into creation and create them additional receptive to changes common. It’s usually robotized, especially programming.

3.Material requirements composing (MRP):

MRP may be a cycle tracing all the method back to the Nineteen Sixties that almost all manufacturers use to ensure adequate materials and components, like subassemblies, square measure accessible to be used within the collection system by taking stock of what’s obtainable, distinctive holes, and buying or creating the leftover things. The focal archive in each MRP and creation composition is the bill of materials (BOM), a complete summing up of the items expected to create associate degree items.MRP is currently and so done as a feature of collection plus composing (MRP II), that widens the MRP plan to completely different offices like time unit and cash.MRP and MRP II were the ancestors of huge business plus composing (ERP), that is meant to include the numerous business cycles of organizations in any business. As you’ll see, SCM can no longer function without ERP software.

4.Stock administration :

Stock administration includes of various ways associate degreed equations for guaranteeing satisfactory stockpile from unrefined parts in an collection plant, perhaps oversaw in a very MRP framework, to bundled merchandise in a very retail location for stripped use of your time and assets.Makers square measure confronted with associate degree assortment of stock administration problems.A considerable ton of that embody organizing requests composing with stock at the 2 closures of the creation interaction. For example, currently and so MRP prompts additional stock significantly once the framework is initially disbursed and also the producer ought to plan to synchronize MRP boundaries with the stock presently offered.

Manual for store network the board :-

The pandemic showed what will happen once the unimaginable falls to items worldwide inventory chains and disturbs life as way as we would be troubled. Viable inventory network the executives will change requests. the things that facilitate gift day cultures square measure fictitious and disseminated by most likely the foremost broad frameworks at any purpose assembled.A worldwide organization of offer chains brings America everything from the manufacture and bundled merchandise that fill market racks to the chips that run our cell phones and also the unrefined parts of recent development. It took an associate degree overall upbeat emergency to cause America to acknowledge precisely the method that delicate these worldwide stock chains square measure.

Presently, 2 years after the start of the COVID-19 pandemic, economies square measure recuperating but offer chains keep drowsy and overpowered. producing plants run at beneath limit since they can’t get natural substances or laborers. Containerships keep a copy at ports, associate degrees there aren’t an adequate range of drivers to convey merchandise crosscountry. The disarray has created a store network, a family word and production network the board a primary concern for a few organizations.Store network the board is an associate degree expansive field that includes all of the cycles, frameworks associate degreed methodologies for up an item’s creation and dispersion. Its various options incorporate interest composing, stock administration, strategies, ability and supplier the board.

Production network the board steps :-

Each important amount of associate item’s development through the inventory network, from materials to creation and dissemination (see Figure 1), has its own clear business cycles and teaches. The bulk of the cycles, that started as paper-based techniques, square measure presently usually restrained in specific inventory networks the executives programming. Here may be a bit by bit depiction of what goes into the store network on the board.

1.Request composing

The SCM interaction begins with looking for what things purchasers want. This stage includes the start phases of inventory network composing, usually thought to be one among the 2 overall categories of SCM aboard store network execution.Production network composing begins with request composing, a cycle for get-together verifiable data, as an example, past deals, and applying investigation and measurable displaying to spur a conjecture or interest arrange that the stretch cluster and useful offices for example, grouping and advertising will decide on. The conjecture decides the types and amounts of things to be fictitious.

Getting the conjecture right is basic for staying far away from steep problems, as an example, the bullwhip impact, during which very little vacillations in retail request square measure amplified additional up the shop network, prompting extreme deficiencies or overflows of stock.A few organizations perform request composing as an element of a formalized interaction referred to as deals and activities composing (S & OP), which contains an associate reiterative course of knowledge gathering, language, accommodating of interest plans with creation plans, and therefore the board endorsement. Many organizations bear in mind S & OP for a lot of in depth interaction referred to as coordinated business composing (IBP) that joins alternative offices’ arrangements in an exceedingly solitary company wide arrangement.

2.Creation composing

In the following important stage, creation composing, the organization makes bound concerning the particulars of wherever and the way the things mixed up within the interest arrange are created.(Creation composing is likewise used in several businesses, like business enterprise and oil and gas.) associate all the a lot of adjusted selection referred to as early arrangement and designing (APS; except, APO for advancement) tries to boost the assets that move into creation and build them a lot of receptive to changes widespread. it’s commonly mechanized in specific programming.

3.Material conditions composing (MRP)

MRP is associate interaction tracing all the means back to the Sixties that almost all producers use to ensure adequate materials and components, like subassemblies, square measure accessible to be used within the grouping system by taking stock of what’s available, characteristic holes, and buying or creating the surplus things.The focal record in each MRP and creation composition is that of the bill of materials (BOM), a complete summing up of the items expected to create associate items.MRP is here and there done as an element of grouping plus composing (MRP II), that widens the MRP plan to completely different divisions like hour and cash.MRP and MRP II were the ancestors of huge business plus composing (ERP), that is meant to coordinate the numerous business cycles of organizations in any business. As you’ll see, ERP programming has become essential to SCM.

4.Stock administration

Stock administration includes various procedures associated with equations for guaranteeing spare stockpiles from natural substances in a grouping plant, perhaps overseen in an exceedingly MRP framework, to bundled products in an exceedingly retail location for smallest use of your time and assets.Makers square measure confronted with an assortment of stock administration problems, an oversized range of that embrace organizing requests composing with stock at the 2 finishes of the creation interaction. For example, in some cases MRP prompts a lot of stock notably once the framework is 1st distributed and therefore the maker ought to plan to synchronize MRP boundaries with the stock presently available.

5.Acquisition

At times referred to as getting, acquisition is the most typical means of trailing down suppliers for merchandise, coping with those connections and obtaining the product financially aboard all the correspondence, like conveyance demands for offers, and table work, together with obtaining requests and solicitations.It is a big space of the production network, the board, considering what proportion is listed in any respect focuses on the chain. Most players within the production network suppliers, makers, merchants and retailers have committed obtention workers.Vital getting may be a raise associated with a lot of fashionable style of acquisition that expects to contour an organization’s getting interaction by exploiting its combined shopping for power and adjusting it to business objectives.Provider relationship the board (SRM), apparently, addresses getting problems by zeroing in on the suppliers the organization considers usually basic to progress and deliberately invigorating associations with them whereas cultivating ideal execution. Figure two shows the SRM interaction in an exceedingly large shell.

6.Operations

Operations covers the moving and golf stroke away of merchandise, from the conveyance of components and unrefined elements to manufacturers of processors to the conveyance of completed things to stores or direct to customers, and even past for item adjusting, come and reusing a cycle referred to as switch methods.Stock administration is arranged in the course of the methods interaction.

Store network the executives steps :-

Each vital amount of Associate in Nursing item’s development through the inventory network, from materials to creation and circulation (see Figure 1), has its own clear business cycles and trains. an oversized portion of the cycles, that started as paper-based ways, an area unit presently generally taken care of specifically to store and network the board programming. Here could be a bit by bit portrayal of what goes into the store network on the board. numerous Links within the provide Chain

Client:The start of the inventory network is that of the consumer. The consumer chooses to shop for Associate in Nursing items and so contacts the reaching cluster of a corporation. A business request is finished with the date of conveyance and also the quantity of the item mentioned. it’d likewise incorporate some for the creation workplace relying upon whether or not or not the item is accessible.

Arranging:Once the consumer has created his/her business request, the composing division can create a creation that will deliver the item sticking out to the necessities of the consumer. At this stage, the composing workplace can understand natural substances needed.

Buying:If unrefined parts are needed, the shopping for division is going to be conversant and so they send shopping requests to the suppliers requesting the redemption of a specific quantity of natural substances on the required date.

Stock:Once the unrefined parts are sent, they’re checked for quality and exactitude and later on placed away in an exceedingly distribution center until they’re expected by the creation division.

Creation:Raw materials area unit stirred to the creation web site, as per the particulars opened up within the creation arrangement. the things expected by the consumer area unit presently created utilizing the unrefined parts provided by the suppliers. The finished things area unit then tried and stirred back to the distribution center contingent upon the date of conveyance expected by the consumer.

Transportation:once the finished item is stirred into capability, the delivery workplace or the transportation division decides once the item passes on the storeroom to hit the consumer on schedule.

Levels of Activities within the provide Chain :-

In order to create certainty that the top of the provider chain is running swimmingly and additionally to make sure most client satisfaction at the bottom attainable price, organizations adopt chain management processes and numerous technologies to help in these processes.

There area unit 3 levels of activities provide Chain Management in this completely different departments of a corporation specialize in to attain the sleek running of the provision chain. They are:

Strategic:At this level, senior management is concerned within the provide chain method and makes selections that concern the complete organization. selections created at this level embrace the scale and web site of the assembly space, the collaborations with suppliers, and also the sort of that product that’s reaching to be factory-made and then forth

Tactical:Military science level of activity focuses on achieving lowest prices for running the provision chain. A number of the ways that this is often done is by making a buying arrangement with the most well-liked suppliers and dealing with transportation corporations for price effective transport.

Operational:At the operational level, activity selections are created on a regular basis and these selections have an effect on however the merchandise shifts on the provision chain. A number of the selections taken at this level embrace taking client orders and also the movement of products from the warehouse to the purpose of consumption.

Technology and provide Chain Management :-

In order to maximize edges from the availability chain management method, organizations got to invest in technology. For the optimum operation of the availability chain management method, organizations primarily invest in Enterprise Resource coming up with suites.Also, the advancement of net technologies permits organizations to adopt Web-based computer code and net communications.

Theories of provide Chain Management:-

A number of consultants within the field of provide chain management have tried theoretical foundations for a few areas of supply chain management by adopting structure theory.

Some of these theories are:

- Resource-Based read (RBV)

- Transaction analysis (TCA)

- Knowledge-Based read (KBV)

- Strategic alternative Theory (SCT)

- Agency Theory (AT)

- Institutional theory (InT)

- Systems Theory (ST)

- Network Perspective (NP)

Audience:

This tutorial is helpful for college students from management streams UN agencies aim to find out the fundamentals of providing Chain Management. Professionals, no matter what sector or trade they belong to, will use this tutorial to find out a way to apply the strategies of providing Chain Management in their several project environments.

Prerequisites:

The readers of this tutorial area unit are expected to possess a general plan of what chain management suggests and what place and importance it holds in a corporation.

Conclusion:

Supply Chain Management could be a branch of management that involves suppliers, makers, supplying suppliers, and most significantly, the shoppers.The supply chain management method works through the implication of a strategic arrangement that ensures the required final result effort of a client with most satisfaction levels at very cheap attainable value. The activities or the functions concerned during this kind of management method are divided into 3 levels: the strategic level, the plan of action level and therefore the operational level.