Cycle Time Vs TAKT Time Vs Lead Time

Last updated on 14th Oct 2020, Artciles, Blog

In a business, various concepts & formulae are used to optimize the entire process, and this article is about three important terms that can be very helpful to your organization. We are talking about Takt Time, Cycle Time, and Lead Time. These are the terms used in multiple industries to optimize the process and deliver better results to their clients. We will also understand the difference between the Takt Time, Cycle Time, and Lead Time in the article, so hang in till the end.

Subscribe For Free Demo

Error: Contact form not found.

What is Takt Time?

Takt is basically a German word for “baton” that a conductor uses in the orchestra to manage the tempo of music. In simple words, Takt means a beat or a pulse in the music. In terms of business, Takt Time means the rate at which the product needs to be manufactured to satisfy the customer demand.

How To Calculate Takt Time (Ideal)?

Suppose you have 500 minutes per day for manufacturing, and the customer demand is 500 units per day, you have 1 minute to produce a unit. That’s your Takt Time.

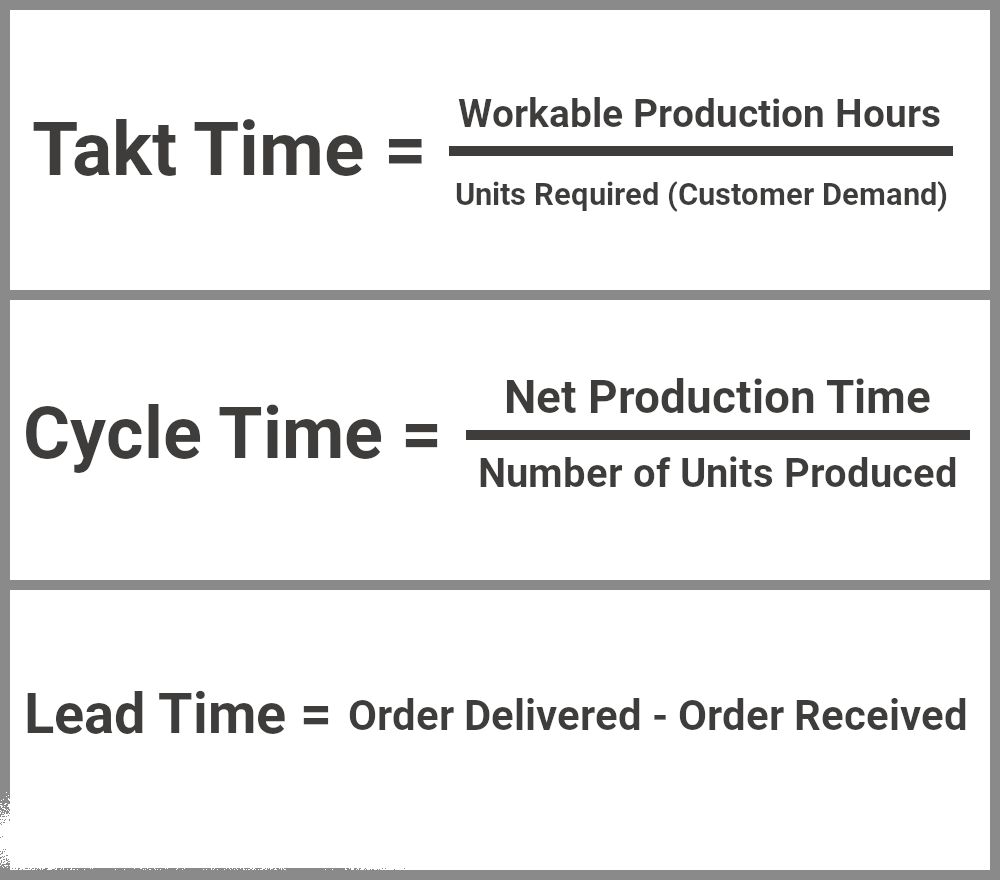

Takt time can be calculated using this simple formula below:

Takt Time = Available Time For Production/Number of Units Required

How To Calculate Takt Time (Real)?

As we all know, ideal calculations are way different than the real situations. So, let’s try and calculate Takt Time using some real conditions.

Total Hours of Working = 8 Hours

Total Minutes of Working = 480 Minutes

Lunch Break = 30 Minutes

Tea Breaks = 2* 15 Minutes = 30 Minutes

Total Productive Minutes = Total Minutes Of Working – (Lunch Break + Tea Breaks)

= 480 – (30+30)

= 420 Minutes

Total Requirements from client = 250 Units/day

Takt time = Total Productive Minutes/Total Requirement

= 420250

= 1.68

What Are The Benefits Of Calculating Takt Time?

There are some important benefits of calculating Takt Time, let’s have a glance:

- You can find the exact time to produce one unit.

- Avoid the situation of overproduction.

- You can decide a precise guideline for the delivery.

- Can also be used to determine the organizational efficiency.

- You can manage overtime calculations.

- Production rate can be streamlined.

What is Cycle Time?

As the name suggests, Cycle Time is the time taken to produce one unit from the start to the end. Cycle time gives you the idea of how much time will it take to complete the demand, according to the current rate.

How To Calculate Cycle Time?

Let’s take an example:

Suppose, your team is working 50 hours a week, producing a total of 100 units. Here’s the formula to calculate the Cycle Time:

Cycle time = No. Of Productive Hours/Total Units Produced

= 50/100

= 0.5 Hour

If your Takt Time is more than 0.5 hour, you must do something about it. But if your Takt Time is below 0.5 hour, everything looks smooth!

Benefits of Calculating Cycle Time

- Gives an actual idea of the production rate.

- Gives data to make changes in the production rate to satisfy the demand.

- Deciding the actual time of delivery.

Takt Time Vs Cycle Time

Takt time and Cycle Time have different uses. In simple terms, Takt Time is to find the maximum time one can spend on one unit before getting the order. Cycle time simply means how much time it takes to complete one unit.

You can simply use Takt Time as the reference to complete the delivery on time. And when you find Cycle Time, your efforts should be about matching it with the Takt Time.

What is Lead Time?

Lead time has different uses compared to Takt Time and Cycle Time. Lead time consists of the entire journey of one unit from the scratch to the end. In simple words, Lead time is the total time taken for a unit from getting an order to receiving payment. So, Lead Time is not only about the production but it is about the entire process of your organization.

How To Calculate Lead Time?

To calculate Lead Time, we must take an example to clearly understand the concept.

Let’s assume, the client gives the order on January 1st. You receive the order on January 2nd. After receiving the order, your team starts the process of manufacturing units on January 3rd. Entire cycle to manufacture the order takes 10 days, so January 13th is the day you complete the manufacturing. Now, the delivery takes about 2 days, so we have reached January 15th. After checking your entire order, the client takes 4 days to make the payment, hence January 19th.

To sum up, the Lead Time for this example will be 19 days. An interesting thing about Lead Time is, no matter how less time you take in manufacturing, you have to cut down other processing time to shorten the Lead Time.

Cycle Time Vs Lead Time

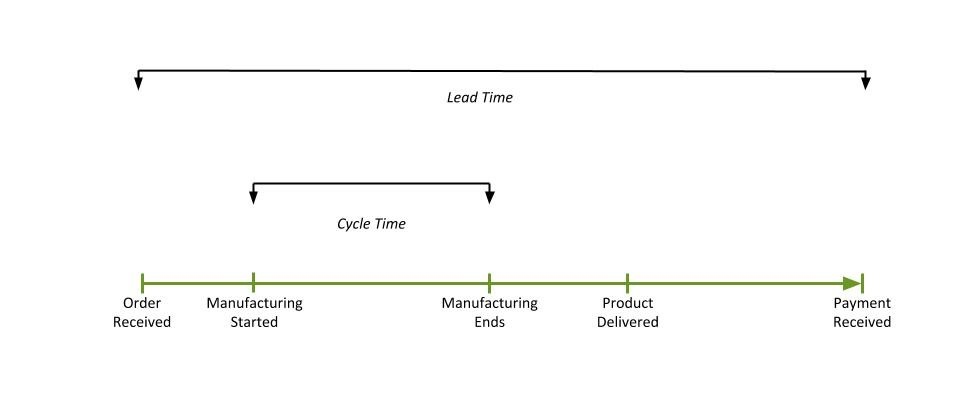

Here is an image that completely explains the difference between Cycle Time and Lead Time. Let’s have a look:

The cycle suggests the manufacturing process of your company, where Lead Time shows the entire process of your company including the Cycle Time. In terms of maths, Cycle Time is the subset of Lead Time.

CT ⊂ LT

Which Business Approach Is Best For Takt Time, Cycle Time, and Lead Time?

Now that we know the importance of all three – Takt Time, Cycle Time, and Lead Time, it’s important to understand which approach you should choose in business.

When it comes to production or manufacturing, your effort should lie in making Cycle Time as close as Takt Time. This approach would help in delivering the order on time.

Talking about the Lead Time, your efforts should lie in making it as short as possible. If you optimize the Cycle Time, then Lead Time will be automatically optimized. Other tasks like planning, packaging, or delivering are included in Lead Time. You can optimize each of these tasks to shorten the Lead Time.

Lead Time vs Cycle Time vs Takt Time

Now that we’ve got the calculations out of the way, you’re probably wondering, what is the difference between these three time metrics? And, even more importantly, how do they work together?

What’s the difference – takt time vs. cycle time?

- While both are essential when it comes to productivity, these two metrics focus on different aspects. Takt accounts for the rate that needs to be achieved to meet demand, while Cycle focuses on the measurement of work done.

- What’s the difference – lead time vs. cycle time? The main difference between these two metrics is the amount of time they take into account. Lead time accounts for the entire order receiving, production, and sales process, whereas Cycle time focuses on production time alone.

- What’s the difference – lead time vs. takt time? While lead time is the total time between receiving an order and delivering an item, takt time focuses on the maximum time your team should spend between starting to work on the item and delivering that item.

In a nutshell, cycle time is internally focused, looking at how long you actually need to produce an item. In turn, takt time focuses on what needs to be achieved in terms of production time to keep up with the demand. Finally, lead time examines your clients’ waiting times (how long it takes you to deliver the order once they have placed it).

Individually they are each extremely helpful in helping you to get to know your business a little better from the inside out. But when combined, they show a fuller picture of how efficiently your company is operating.

- If your takt time is high, in order to meet demand, you’ll need to increase your cycle time.

- By knowing your lead time, you can predict how long processing an order takes for your clients – aka wait time.

- All this together indicates how satisfied your customers are likely to be.

By keeping all these times in check, you can improve the efficiency of your business and boost client satisfaction.

Understanding Manufacturing Time

A common mistake when considering if production is able to meet a customer’s demand is to only look at takt and cycle times. An order often can’t help a customer until it is received. While part of lead time; cycle times don’t include two things …

- The time between placing an order and starting production

- The time from the order’s completion to delivery

These times should not be forgotten when calculating deadlines. Subtracting these times from the workable hours in the takt time formula might be an easy way to stay on schedule. Using takt, cycle, and lead times will require some level of consistency and repeatability. Including tool changes, maintenance, and a plan for unexpected downtime will improve accuracy in these times.

Find the best way to obtain and document accurate times. Involving workers in data collection can take away their time, focus, and motivation. Accurate or not, takt and cycle times that have workers walking around with stopwatches writing downtimes or timers constantly reminding them that another action or part should have been completed could cause fatigue both physically and emotionally. Maintaining skilled workers is important to maintaining or reducing cycle and lead times. Don’t lose, upset, or slow down valuable employees over stopwatches and forms. Instead leverage machine monitoring solutions that automatically track machine performance, including downtime and cycle time, and provide insight at multiple levels of the organization.

Reducing lead times and cycle times requires organization, control, and tracking. One way is to reduce unplanned downtime. A driver of IoT and connected products, predictive maintenance reduces equipment downtime which can greatly reduce process, cycle, and lead times. There are many technologies available, but first, find accurate times and machine data to determine where a solution would have the greatest impact to reduce cycle times and reduce lead times.

Using takt times with cycle and lead times should create informed managers that understand how to mitigate or add resources to hit needed production demands, not distract or add paperwork to a worker’s day. Lead times, cycle times, and takt times have simple formulas. However, the way these times are obtained and used will determine how well a company is able to control production to stay on the cutting edge.

Are you looking training with Right Jobs?

Contact Us- What is SAP Certification?

- Certified Information Systems Security Professional (CISSP) Certification

- What Is SAP Human Capital Management (HCM)?

- What Is Standardized Work, SWIP and One piece flow?

- Togaf Interview Questions and Answers

Related Articles

Popular Courses

- Lean Training

11025 Learners - Jira Training

12022 Learners - PMi Training

11141 Learners

- What is Dimension Reduction? | Know the techniques

- Difference between Data Lake vs Data Warehouse: A Complete Guide For Beginners with Best Practices

- What is Dimension Reduction? | Know the techniques

- What does the Yield keyword do and How to use Yield in python ? [ OverView ]

- Agile Sprint Planning | Everything You Need to Know