- Agile Sprint Planning | Everything You Need to Know

- What is Project Management Process ? : A Complete Guide

- What is Lean Management? : A Complete Guide

- What is ITIL ? Know about the Framework

- What is Six Sigma?| Know the tools used

- What is Kanban Training?|Know more about it

- Project Management Tools and Techniques : A Complete Guide

- What is Project Management? Everything You need to Know | Salary for the role

- Srum Org Certification? All you need to know about it

- MS Project Certification | All you need to know

- What is Project Manager? Know about the salary

- Six Sigma Certification Cost | Know all details about it

- Difference Between PMO and Project Manager? | Expert’s Top Picks

- What are Project Management Tools | Its Techniques | Everything You Need to Know

- What is Agile |Its Methodology and Types | How to Implement [ OverView ]

- What is a Product Roadmap? | How to Create one | A Complete Guide with Best Practices

- Scrum vs Kanban | Agile at Scale | New Agile BenchMark

- How to Effectively Manage Stakeholders | A Complete Guide For Beginners with Experts Top Picks

- What is Scaled Agile Framework (SAFe) | The Leading Framework For Business Agility | Everything You Need to Know

- How to Become a Project Manager | A Definitive Guide with Best Practices

- Time Management Tools to Help You Succeed as a Professional | Expert’s Top Picks

- Top 10 Tips for Agile Sprint Planning To Implement Efficient Marketing | Step-By-Step Process with REAL-TIME Examples

- What is ICP-ACC (ICAgile Certified Agile Coaching)? | A Definitive Guide with Best Practices [ OverView ]

- How To Run An Effective Agile Retrospective-Agile management | Everything You Need to Know

- What Skills Does One Acquire After The PMP Certification?

- A Definitive Guide: Most Effective and Proven Time Management Techniques [ OverView ]

- What Gaps I Filled After CSM Certification For my Scrum Project? [ OverView ]

- How to Create A Plan And Manage Your Projects Better?: Step-By-Step Process [ OverView ]

- What is User Story Mapping? : A Complete Guide with Best Practices

- What is Design Thinking ? : Benefits and Special Features | A Definitive Guide with Best Practices

- What is the Capability Maturity Model (CMM) [ For Freshers and Experience ]

- What is Sprint Planning ? | A Definitive Guide | Step-By-Step Process with REAL-TIME Examples

- What is Total Productive Maintenance (TPM) and How Does It Help in Equipment Effectiveness [ OverView ]

- What are Agile Metrics ? : A Complete Guide For Beginners [ OverView ]

- What is Agile Marketing and Why Do You Need It | Step-By-Step Process with REAL-TIME Examples

- Why is Retrospection Needed? : A Complete Guide For Beginners [ OverView ]

- Developing Project Schedule : Role of Float, Leads, and Lags [ OverView ]

- Project Life Cycle vs Product Life Cycle | Know Their Differences and Which Should You Learn?

- Projects in Business Environments | A Complete Guide For Beginners [ OverView ]

- What is Business Agility ? and Why is it Important ? Expert’s Top Picks

- The Most Important Benefits of Blended Learning | A Complete Guide For Beginners

- Can Business Analyst be a Project Manager? : Expert’s Top Picks

- Why A PMO Is Second In Line To A Project Manager ? | Expert’s Top Picks

- Devops vs Waterfall | A Definitive Guide and Which Should You Learn?

- Jira vs Trello | Know Their Differences and Which Should You Learn?

- Key Values and Principles Behind the Agile Manifesto | A Definitive Guide

- What are Scrum Ceremonies : The Ultimate Guide with Expert’s Top Picks

- Business Analyst vs Financial Analyst | Know Their Differences and Which Role is Better ?

- Learn Burndown Charts With Jira : Comprehensive Guide [ For Freshers and Experience ]

- What Is Scrum XP? : Step-By-Step Process with REAL-TIME Examples

- Phases of Project Management | Step-By-Step Process | Expert’s Top Picks

- Project Manager Salary in India – How much does a PM earn? [ Job & Future ]

- Why Do Scrum Masters Get Paid so Much? [For Freshers and Experience]

- What Best Describes a Scrum Team? All you need to know [ OverView ]

- JIRA vs TFS | Differences and Which Should You Learn?

- Anti-patterns of a Scrum Master : Step-By-Step Process

- SCM Tools and Frameworks | A Complete Guide with Best Practices

- Stages of Team Development | Everything You Need to Know

- Project Management Consultant : Job Description, Skills Required | Everything You Need to Know

- CSM vs PSM : Difference You Should Know

- Top Characteristics of a Project Manager : Expert’s Top Picks

- Roles And Responsibilities Of A Product Owner : Everything You Need to Know

- Common Project Risks and How to Tackle Them | Expert’s Top Picks

- Benefits of Having Shorter Sprints in Agile – Everything You Need to Know

- Group Discussion Tips | A Complete Guide with Best Practices

- PMP Certification Cost : All you need to know

- DMAIC Process and Methods | All you need to know [ OverView ]

- Agile Scrum Vs Kanban | Know the difference

- Deming vs Juran vs Crosby

- What is Project Scope Management and Why It’s Important?

- The Basic Principles of Project Management

- Top PMP Exam Questions and Answers for 2020

- Risk Management Strategies

- Roles and Responsibilities of A Scrum Master

- ROM Estimate Vs Definitive Estimate

- Guidelines for Creating and Maintaining a WBS Dictionary

- How to Become a Certified ScrumMaster?

- Top Professional Skills for 2020

- Fast Tracking Vs Crashing

- PMP Vs PRINCE2 Vs CAPM

- PMP Earned Value Management (EVM) And Formulas

- What is Certified Scrum Professional (CSM)?

- Top Leadership Theories Every Manager Should Know

- What is Deliverables in Project Management?

- How To Prepare For TOEFL

- History and evolution of the PMP Certification

- What Is Float In Microsoft Project?

- Rules to set you up for success in project

- What is Scrum Project Management?

- What Is Estimating Activity Duration in Project Management?

- What Are The PMP Terminologies Relating To Cost Knowledge Area?

- What is Project Scope Management processes?

- What Are The Types of Organization In PMP?

- Books to Beat the Scrum Master Certification

- Agile Coach Vs Agile Consultant

- What is the cost of quality in project management?

- Signs Your Career May Be Stagnation and Tips to Overcome Downturn

- Certified ScrumMaster (CSM) Certification

- Lean Six Sigma Black Belt Certification

- What is schedule Activity in project management?

- Why Do We Need a Project Charter?

- PMP Certification Exam Preparation Mind Map

- Why Quality Professionals Should Use Infographics In Project Management?

- Role of Earned Value Technique in Project Management

- What is Project Quality Management?

- Tools and Techniques to Estimate Project Cost

- What is a Project Charter And Project Scope in Project Management?

- Why Should You Conduct Project Status Meetings with Your Team?

- The 7 R’s of Change Management

- What Are The Categories and sources of risk in your project?

- What Is a Network Diagram in Project Management?

- What are The Types of Contracts In PMP?

- Residual Risk Vs Secondary Risk

- Impact of the stakeholders on the projects

- Effort Vs Duration Vs Elapsed Time

- Agile vs Scrum

- What Is Six Sigma Quality Assurance?

- How to Close a Project?

- What Qualifications Do You Need to be a Project Manager?

- Project Management Vs General Operations Management

- Enterprise Environmental Factors & Organizational Process Assets

- What is a project manager?

- Important Questions for PMP Certification Exam

- How is the PMP Exam changing, in 2015 & 2020?

- How To Renew Your PMP Certification?

- The Importance of Having Project Acceptance Criteria in Your Projects

- Tips for PMP Exam Preparation

- What is requirement traceability matrix RTM in Project Management?

- Poor Performance Appraisal? Here are the tips to turn any negative feedback into positive.

- How to build a successful Career in Agile and Scrum?

- Importance of Tuckman ladder model in HR management

- How To Apply For The PMP® Exam In Easy Steps

- How to Write a Six Sigma Problem Statement

- What is a lessons learned document in PMI?

- Perform Quality Assurance Vs Perform Quality Control

- How to Improve Quality Management Consistently?

- Interactive Vs Push Vs Pull Communication

- what is risk management?

- Key Appraisal Questions to Prepare For

- What are the MSP Certifications?

- What Is A Six Sigma Control Plan?

- How to Create a Project Plan in Excel?

- Agile Prioritization Techniques

- Tips to Help Millennials Climb the Corporate Ladder

- What is an Issue Log?

- Advantages of PMP over MBA

- Top Successful Project Estimation Techniques

- PMP Examination Preparation – ITTO’s

- Employee Training Rewards That Actually Improve Learning

- Lean principles

- What Does It Take to Become a Successful Agile Coach

- Projects VS Programs

- The Role of Six Sigma in Manufacturing

- The Top Formulas to Memorize Before Your PMP Exam

- Roadmap to CSM (Certified Scrum Master) Certification

- What are Some Qualities of a Good Manager and Good Leader?

- How to Handle Project Monitoring and Controlling Processes?

- Top Free Agile Tools For Any Project Manager

- Risk Assessment in Project Management

- The Concept of Zero Defects in Quality Management

- The Importance of Work Packages in Project Scope Management

- How to Get Project Management Experience for PMP Certification

- Different Ways to Calculate the Estimate at Completion (EAC)

- What Is a ScrumMaster?

- What is Risk Register?

- Agile Certifications

- Top-down Approach Vs Bottom-up Approach

- Leadership Vs Management

- What is Feasibility Study and Its Importance in Project Management?

- What Is a Project Management Plan?

- The Professional Advantages of the CAPM Certification

- PRINCE2 Vs PMP

- Rita Mulcahy’s PMP Prep and PMBOK® Guide

- What is Project Cycle Management?

- What is Project and Process Metrics?

- PMBOK® Sixth Edition is Here! What Project Managers Should Know?

- CAPM Certification

- Top Project Selection Methods for Project Managers

- Free Float Vs Total Float

- What is Critical Chain Project Management?

- How to Build a Career in Project Management?

- Scrum Master or Product Owner: What Suits You Better?

- Project Documentation and its Importance

- What is Performance Reporting in the Project Management?

- Top Highest Paying Tech Jobs in India

- Agile Sprint Planning | Everything You Need to Know

- What is Project Management Process ? : A Complete Guide

- What is Lean Management? : A Complete Guide

- What is ITIL ? Know about the Framework

- What is Six Sigma?| Know the tools used

- What is Kanban Training?|Know more about it

- Project Management Tools and Techniques : A Complete Guide

- What is Project Management? Everything You need to Know | Salary for the role

- Srum Org Certification? All you need to know about it

- MS Project Certification | All you need to know

- What is Project Manager? Know about the salary

- Six Sigma Certification Cost | Know all details about it

- Difference Between PMO and Project Manager? | Expert’s Top Picks

- What are Project Management Tools | Its Techniques | Everything You Need to Know

- What is Agile |Its Methodology and Types | How to Implement [ OverView ]

- What is a Product Roadmap? | How to Create one | A Complete Guide with Best Practices

- Scrum vs Kanban | Agile at Scale | New Agile BenchMark

- How to Effectively Manage Stakeholders | A Complete Guide For Beginners with Experts Top Picks

- What is Scaled Agile Framework (SAFe) | The Leading Framework For Business Agility | Everything You Need to Know

- How to Become a Project Manager | A Definitive Guide with Best Practices

- Time Management Tools to Help You Succeed as a Professional | Expert’s Top Picks

- Top 10 Tips for Agile Sprint Planning To Implement Efficient Marketing | Step-By-Step Process with REAL-TIME Examples

- What is ICP-ACC (ICAgile Certified Agile Coaching)? | A Definitive Guide with Best Practices [ OverView ]

- How To Run An Effective Agile Retrospective-Agile management | Everything You Need to Know

- What Skills Does One Acquire After The PMP Certification?

- A Definitive Guide: Most Effective and Proven Time Management Techniques [ OverView ]

- What Gaps I Filled After CSM Certification For my Scrum Project? [ OverView ]

- How to Create A Plan And Manage Your Projects Better?: Step-By-Step Process [ OverView ]

- What is User Story Mapping? : A Complete Guide with Best Practices

- What is Design Thinking ? : Benefits and Special Features | A Definitive Guide with Best Practices

- What is the Capability Maturity Model (CMM) [ For Freshers and Experience ]

- What is Sprint Planning ? | A Definitive Guide | Step-By-Step Process with REAL-TIME Examples

- What is Total Productive Maintenance (TPM) and How Does It Help in Equipment Effectiveness [ OverView ]

- What are Agile Metrics ? : A Complete Guide For Beginners [ OverView ]

- What is Agile Marketing and Why Do You Need It | Step-By-Step Process with REAL-TIME Examples

- Why is Retrospection Needed? : A Complete Guide For Beginners [ OverView ]

- Developing Project Schedule : Role of Float, Leads, and Lags [ OverView ]

- Project Life Cycle vs Product Life Cycle | Know Their Differences and Which Should You Learn?

- Projects in Business Environments | A Complete Guide For Beginners [ OverView ]

- What is Business Agility ? and Why is it Important ? Expert’s Top Picks

- The Most Important Benefits of Blended Learning | A Complete Guide For Beginners

- Can Business Analyst be a Project Manager? : Expert’s Top Picks

- Why A PMO Is Second In Line To A Project Manager ? | Expert’s Top Picks

- Devops vs Waterfall | A Definitive Guide and Which Should You Learn?

- Jira vs Trello | Know Their Differences and Which Should You Learn?

- Key Values and Principles Behind the Agile Manifesto | A Definitive Guide

- What are Scrum Ceremonies : The Ultimate Guide with Expert’s Top Picks

- Business Analyst vs Financial Analyst | Know Their Differences and Which Role is Better ?

- Learn Burndown Charts With Jira : Comprehensive Guide [ For Freshers and Experience ]

- What Is Scrum XP? : Step-By-Step Process with REAL-TIME Examples

- Phases of Project Management | Step-By-Step Process | Expert’s Top Picks

- Project Manager Salary in India – How much does a PM earn? [ Job & Future ]

- Why Do Scrum Masters Get Paid so Much? [For Freshers and Experience]

- What Best Describes a Scrum Team? All you need to know [ OverView ]

- JIRA vs TFS | Differences and Which Should You Learn?

- Anti-patterns of a Scrum Master : Step-By-Step Process

- SCM Tools and Frameworks | A Complete Guide with Best Practices

- Stages of Team Development | Everything You Need to Know

- Project Management Consultant : Job Description, Skills Required | Everything You Need to Know

- CSM vs PSM : Difference You Should Know

- Top Characteristics of a Project Manager : Expert’s Top Picks

- Roles And Responsibilities Of A Product Owner : Everything You Need to Know

- Common Project Risks and How to Tackle Them | Expert’s Top Picks

- Benefits of Having Shorter Sprints in Agile – Everything You Need to Know

- Group Discussion Tips | A Complete Guide with Best Practices

- PMP Certification Cost : All you need to know

- DMAIC Process and Methods | All you need to know [ OverView ]

- Agile Scrum Vs Kanban | Know the difference

- Deming vs Juran vs Crosby

- What is Project Scope Management and Why It’s Important?

- The Basic Principles of Project Management

- Top PMP Exam Questions and Answers for 2020

- Risk Management Strategies

- Roles and Responsibilities of A Scrum Master

- ROM Estimate Vs Definitive Estimate

- Guidelines for Creating and Maintaining a WBS Dictionary

- How to Become a Certified ScrumMaster?

- Top Professional Skills for 2020

- Fast Tracking Vs Crashing

- PMP Vs PRINCE2 Vs CAPM

- PMP Earned Value Management (EVM) And Formulas

- What is Certified Scrum Professional (CSM)?

- Top Leadership Theories Every Manager Should Know

- What is Deliverables in Project Management?

- How To Prepare For TOEFL

- History and evolution of the PMP Certification

- What Is Float In Microsoft Project?

- Rules to set you up for success in project

- What is Scrum Project Management?

- What Is Estimating Activity Duration in Project Management?

- What Are The PMP Terminologies Relating To Cost Knowledge Area?

- What is Project Scope Management processes?

- What Are The Types of Organization In PMP?

- Books to Beat the Scrum Master Certification

- Agile Coach Vs Agile Consultant

- What is the cost of quality in project management?

- Signs Your Career May Be Stagnation and Tips to Overcome Downturn

- Certified ScrumMaster (CSM) Certification

- Lean Six Sigma Black Belt Certification

- What is schedule Activity in project management?

- Why Do We Need a Project Charter?

- PMP Certification Exam Preparation Mind Map

- Why Quality Professionals Should Use Infographics In Project Management?

- Role of Earned Value Technique in Project Management

- What is Project Quality Management?

- Tools and Techniques to Estimate Project Cost

- What is a Project Charter And Project Scope in Project Management?

- Why Should You Conduct Project Status Meetings with Your Team?

- The 7 R’s of Change Management

- What Are The Categories and sources of risk in your project?

- What Is a Network Diagram in Project Management?

- What are The Types of Contracts In PMP?

- Residual Risk Vs Secondary Risk

- Impact of the stakeholders on the projects

- Effort Vs Duration Vs Elapsed Time

- Agile vs Scrum

- What Is Six Sigma Quality Assurance?

- How to Close a Project?

- What Qualifications Do You Need to be a Project Manager?

- Project Management Vs General Operations Management

- Enterprise Environmental Factors & Organizational Process Assets

- What is a project manager?

- Important Questions for PMP Certification Exam

- How is the PMP Exam changing, in 2015 & 2020?

- How To Renew Your PMP Certification?

- The Importance of Having Project Acceptance Criteria in Your Projects

- Tips for PMP Exam Preparation

- What is requirement traceability matrix RTM in Project Management?

- Poor Performance Appraisal? Here are the tips to turn any negative feedback into positive.

- How to build a successful Career in Agile and Scrum?

- Importance of Tuckman ladder model in HR management

- How To Apply For The PMP® Exam In Easy Steps

- How to Write a Six Sigma Problem Statement

- What is a lessons learned document in PMI?

- Perform Quality Assurance Vs Perform Quality Control

- How to Improve Quality Management Consistently?

- Interactive Vs Push Vs Pull Communication

- what is risk management?

- Key Appraisal Questions to Prepare For

- What are the MSP Certifications?

- What Is A Six Sigma Control Plan?

- How to Create a Project Plan in Excel?

- Agile Prioritization Techniques

- Tips to Help Millennials Climb the Corporate Ladder

- What is an Issue Log?

- Advantages of PMP over MBA

- Top Successful Project Estimation Techniques

- PMP Examination Preparation – ITTO’s

- Employee Training Rewards That Actually Improve Learning

- Lean principles

- What Does It Take to Become a Successful Agile Coach

- Projects VS Programs

- The Role of Six Sigma in Manufacturing

- The Top Formulas to Memorize Before Your PMP Exam

- Roadmap to CSM (Certified Scrum Master) Certification

- What are Some Qualities of a Good Manager and Good Leader?

- How to Handle Project Monitoring and Controlling Processes?

- Top Free Agile Tools For Any Project Manager

- Risk Assessment in Project Management

- The Concept of Zero Defects in Quality Management

- The Importance of Work Packages in Project Scope Management

- How to Get Project Management Experience for PMP Certification

- Different Ways to Calculate the Estimate at Completion (EAC)

- What Is a ScrumMaster?

- What is Risk Register?

- Agile Certifications

- Top-down Approach Vs Bottom-up Approach

- Leadership Vs Management

- What is Feasibility Study and Its Importance in Project Management?

- What Is a Project Management Plan?

- The Professional Advantages of the CAPM Certification

- PRINCE2 Vs PMP

- Rita Mulcahy’s PMP Prep and PMBOK® Guide

- What is Project Cycle Management?

- What is Project and Process Metrics?

- PMBOK® Sixth Edition is Here! What Project Managers Should Know?

- CAPM Certification

- Top Project Selection Methods for Project Managers

- Free Float Vs Total Float

- What is Critical Chain Project Management?

- How to Build a Career in Project Management?

- Scrum Master or Product Owner: What Suits You Better?

- Project Documentation and its Importance

- What is Performance Reporting in the Project Management?

- Top Highest Paying Tech Jobs in India

Lean principles

Last updated on 01st Oct 2020, Artciles, Blog, Project Management

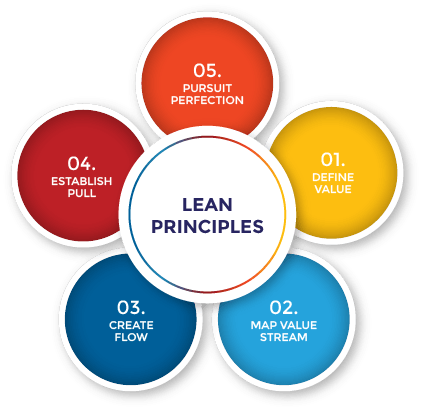

Lean manufacturing, or lean production, is a production method derived from Toyota’s 1930 operating model “The Toyota Way” (Toyota Production System, TPS). The term “Lean” was coined in 1988 by John Krafcik, and defined in 1996 by James Womack and Daniel Jones to consist of five key principles

Subscribe For Free Demo

Error: Contact form not found.

1. Define Value

To better understand the first principle of defining customer value, it is important to understand what value is. Value is what the customer is willing to pay for. It is paramount to discover the actual or latent needs of the customer. Sometimes customers may not know what they want or are unable to articulate it. This is especially common when it comes to novel products or technologies. There are many techniques such as interviews, surveys, demographic information, and web analytics that can help you decipher and discover what customers find valuable. By using these qualitative and quantitative techniques you can uncover what customers want, how they want the product or service to be delivered, and the price that they afford.

2. Map the Value Stream

The second Lean principle is identifying and mapping the value stream. In this step, the goal is to use the customer’s value as a reference point and identify all the activities that contribute to these values. Activities that do not add value to the end customer are considered waste. The waste can be broken into two categories: non-valued added but necessary and non-value & unnecessary. The later is pure waste and should be eliminated while the former should be reduced as much as possible. By reducing and eliminating unnecessary processes or steps, you can ensure that customers are getting exactly what they want while at the same time reducing the cost of producing that product or service.

3. Create Flow

After removing the wastes from the value stream, the following action is to ensure that the flow of the remaining steps run smoothly without interruptions or delays. Some strategies for ensuring that value-adding activities flow smoothly include: breaking down steps, reconfiguring the production steps, leveling out the workload, creating cross-functional departments, and training employees to be multi-skilled and adaptive.

4. Establish Pull

Inventory is considered one of the biggest wastes in any production system. The goal of a pull-based system is to limit inventory and work in process (WIP) items while ensuring that the requisite materials and information are available for a smooth flow of work. In other words, a pull-based system allows for Just-in-time delivery and manufacturing where products are created at the time that they are needed and in just the quantities needed. Pull-based systems are always created from the needs of the end customers. By following the value stream and working backwards through the production system, you can ensure that the products produced will be able to satisfy the needs of customers.

5. Pursue Perfection

Wastes are prevented through the achievement of the first four steps: 1) identifying value, 2) mapping value stream, 3) creating flow, and 4) adopting a pull system. However, the fifth step of pursuing perfection is the most important among them all. It makes Lean thinking and continuous process improvement a part of the organizational culture. Every employee should strive towards perfection while delivering products based on the customer needs. The company should be a learning organization and always find ways to get a little better each and every day.

What is waste in Lean Manufacturing?

A core principle in lean methodology is the removal of waste within an operation. And in any business, one of the heaviest drains on profitability is waste. Lean waste can come in the form of time, material, and labor. But it may also be related to the utilization of skill-sets as well as poor planning. In lean manufacturing, waste is any expense or effort that is expended but which does not transform raw materials into an item the customer is willing to pay for. By optimizing process steps and eliminating waste, only true value is added at each phase of production.

The Lean Manufacturing model recognizes 8 types of waste within an operation; seven originally conceived when the Toyota Production System was first conceived, and an eighth added when lean methodology was adopted within the Western World. Seven of the eight wastes are production process oriented, while the eighth waste is directly related to management’s ability to utilize personnel.

The 8 wastes of lean manufacturing include:

- Defects

- Excess Processing

- Overproduction

- Waiting

- Inventory

- Transportation

- Motion

- Non-Utilized Talent

Conclusion

The five Lean principles provide a framework for creating an efficient and effective organization. Lean allows managers to discover inefficiencies in their organization and deliver better value to customers. The principles encourage creating better flow in work processes and developing a continuous improvement culture. By practicing all 5 principles, an organization can remain competitive, increase the value delivered to the customers, decrease the cost of doing business, and increase their profitability.