What is the cost of quality in project management?

Last updated on 10th Oct 2020, Artciles, Blog

Cost of quality, or COQ, refers to the total costs needed to bring products or services up to standards defined by project management professionals. To determine the cost of quality, combine the costs of conformance and the costs of non-conformance. A closer look at both these costs will help you better prepare for the cost of quality PMP exam questions.

Subscribe For Free Demo

Error: Contact form not found.

What Is Cost of Quality?

Cost of Quality (COQ) is primarily a measure of all costs related to the quality and the lack thereof. In other words, it an integrated concept of the costs to achieve quality and the costs that occur due to quality issues. Thereby, COQ refers to the entire lifecycle of the product (or outcome) created by a project.

The cost of quality technique addresses the issue of a project being temporary in nature while the quality of its deliverables lasts for the entire lifecycle of the product. Thus, it forces a project and its organization to measure to consider quality aspects during and beyond the duration of a project.

In this context, the PMBOK suggests that COQ be managed by a unit outside of the project such as the program management or product management divisions.

Cost of quality consists of two components:

- Cost of conformance and

- Cost of non-conformance, also referred to as failure cost.

These building blocks of COQ represent the interdependencies between investing in quality during the project and the future costs of not doing so. We will introduce these components in the next sections, followed by an illustrative example.

Cost of quality is a technique used in several processes of the Project Quality Management Knowledge Area (PMBOK, ch. 8). It is also a technique of the Estimating Cost and Determine Budget processes.

What Is Cost of Conformance?

Cost of conformance describes the amount of resources needed to achieve the quality requirements and targets of a project. The underlying rationale is to spend money on the prevention of quality issues rather than for fixing them.

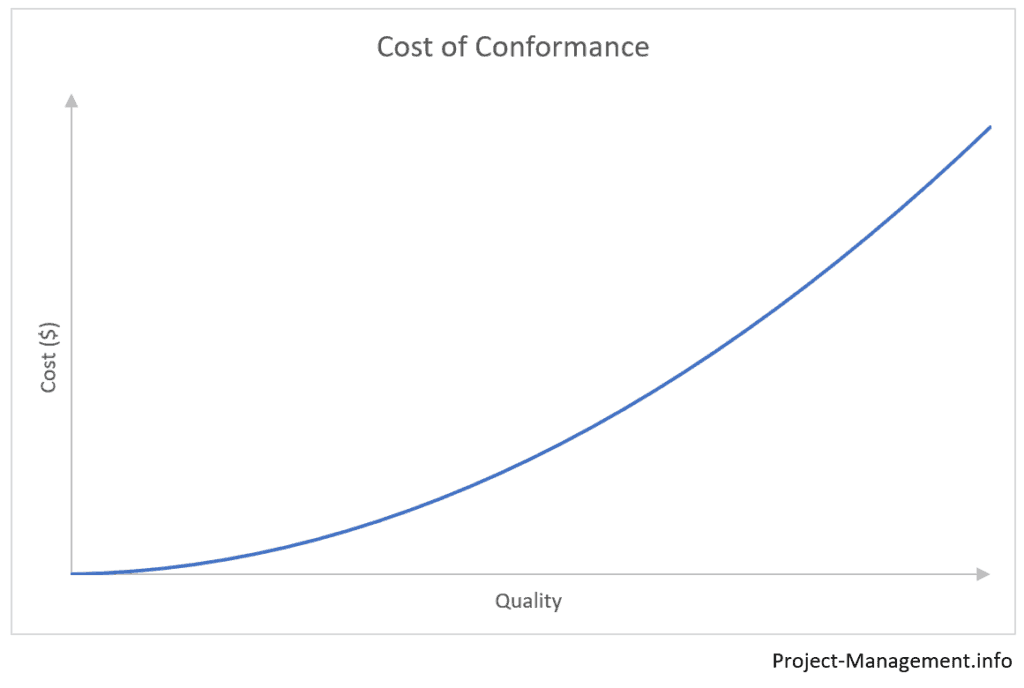

In practice, cost of conformance comes often with the characteristic of a diminishing marginal utility (see example below). This means that the first dollar spent will massively increase the quality of the project deliverables while the curve is flattening a bit with every additional dollar spent. In other words: the ‘bang for the buck’ is high in the beginning and declines as the costs of conformance increase. This effect is illustrated in the below chart.

This chart shows the effect of diminishing marginal utility for cost of conformance – in other words: the more money spent, the lower the quality increase for each additional dollar.

Cost of conformance consist of two components:

- Prevention cost and

- Appraisal cost.

Prevention Costs

The term prevention cost refers to money spent on actions and material that facilitate the creation of a quality deliverable (e.g. a product). This basically includes all the resources required to build quality into the product.

The PMBOK lists

- training,

- documentation,

- equipment, and

- sufficient time

as examples of prevention measures. However, this group may also include other areas such as

- proper staffing of projects (getting the “best person for the job”),

- market intelligence and lessons learned with respect to similar projects,

- creating “spikes” (i.e. pilots) to test different approaches and choose the right one, as well as

- any other activity that helps increase the quality of the output.

Appraisal costs are the (financial and non-financial) resources that are consumed to assess and measure the quality of the deliverables of a project. This relates to quality assurance and money invested in activities that identify quality issues. Thus, corrective actions can be taken, and issues can be fixed during the project.

Examples provided by the PMBOK are:

- testing,

- destructive testing loss (i.e. testing the durability of a product which can involve losing the amount spent to produce that piece; crash tests are an example of destructive testing), and

- inspections or quality checks.

Other types of appraisal costs are

- external quality audits,

- measurement of quality indicators (e.g. quality gates), and

- mystery shopping (i.e. testing a product or service from a customer’s perspective).

The constituents of this and other cost types may vary among different organizations. At the end of the day, this type of prevention cost should basically cover any resource consumption related to the assessment of quality during a project.

What Is Cost of Non-Conformance?

Cost of non-conformance is used as a synonym for failure cost. It refers to the resources that are required to fix failures and take corrective actions but also to indirect effects from quality issues, such as negative business impact.

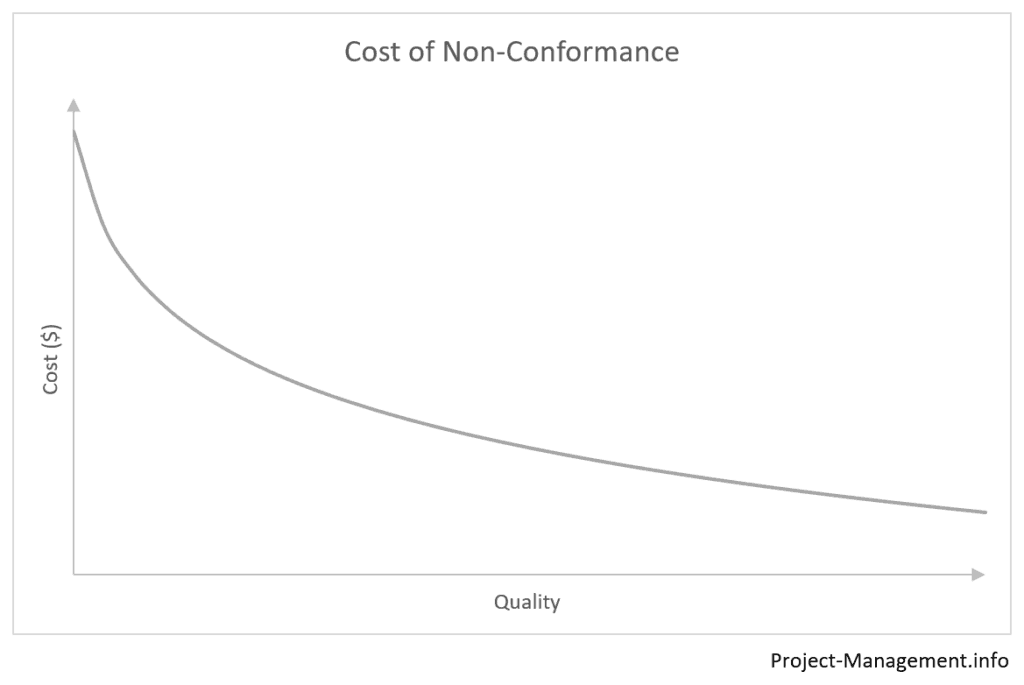

While the amount spent on cost of conformance is determining the level of quality, cost of non-conformance is a function of that level of quality. As a rule of thumb, the higher the quality the lower the cost of non-conformance. This chart illustrates this effect with a sample curve of non-conformance cost.

Considering cost of non-conformance as a function of quality, it is also subject to diminishing marginal utility, reflected in a flattening curve. In other words: the higher the quality the lower the saved non-conformance cost per quality unit.

Cost of non-conformance consists of two elements:

- Internal failure costs and

- External failure costs.

Internal failure costs are costs for those failures that are discovered by the project or the organization itself. External failure costs are referring to resources required to address customer complaints or lost business due to customer dissatisfaction.

Internal Failure Costs

Internal failure costs relate to corrective actions taken to fix failures that were identified within a project or an organization. The PMBOK mentions rework and scrap as examples.

In practice, IT projects sometimes encounter a bunch of defects, while construction projects may realize that in some cases not all fire prevention requirements have been met, for instance.

Both examples would inevitably lead to rework which requires additional resources, i.e. the internal failure costs.

External Failure Costs

The category external failure costs covers the costs that are spent to respond to customer complaints on the quality of a product or deliverable. It also considers indirect effects such as a negative impact on sales and overall business.

According to the PMI methodology, this type of non-conformance costs includes inter alia

- liabilities,

- warranty work,

- lost business (i.e. losses arising from customers not doing business with a company because of previous or current quality issues).

While this type of failure cost is often hard to measure and even harder to predict, it is crucial to make the COQ concept work. This is because external failure costs tend to cause a massive impact if they occur.

Customer satisfaction is a goal of almost all companies and quality issues could lead to a quickly deteriorating reputation of a product or a brand – which is often followed by declining sales, prices and lower revenues.

In projects driven by legal and regulatory requirements, external failure costs can be fatal for an organization and even put their viability at risk. Examples are plants or buildings that cannot be used or products that cannot be launched due to noncompliance with legal requirements. In some industries, companies could even lose their license to continue or commence their business.

Although COQ is not a brand-new concept, quality issues occur regularly and even reputable companies have been heavily hit by external failure costs. Just think of exploding phone and laptop batteries, delayed infrastructure projects or pharmaceutical companies with billions of sunk costs for medicine that eventually did not get approved by the authorities.

How to Calculate Cost of Quality in Projects?

While the assessment and prediction of the components of cost of quality (especially the failure costs) are challenging, the calculation of COQ itself is rather straightforward. The formula to calculate cost of quality is:

COQ = Cost of Conformance + Cost of Non-Conformance (or failure costs)

where:

cost of conformance = sum of the prevention and appraisal costs,

cost of non-conformance = sum of external and internal failure costs.

How to Interpret and Optimize Cost of Quality in Projects?

The concept of cost of quality may look a bit theoretical at first sight. However, there are certain practical considerations stemming from this concept:

As absolute perfection is usually not achievable, costs of quality are subject to a cost-benefit analysis (which is also suggested in the PMBOK).

To optimize the overall cost of quality, the project manager has to determine the optimal balance between the cost of conformance incurred during the project and the cost of non-conformance that are accepted for the entire lifecycle of the product.

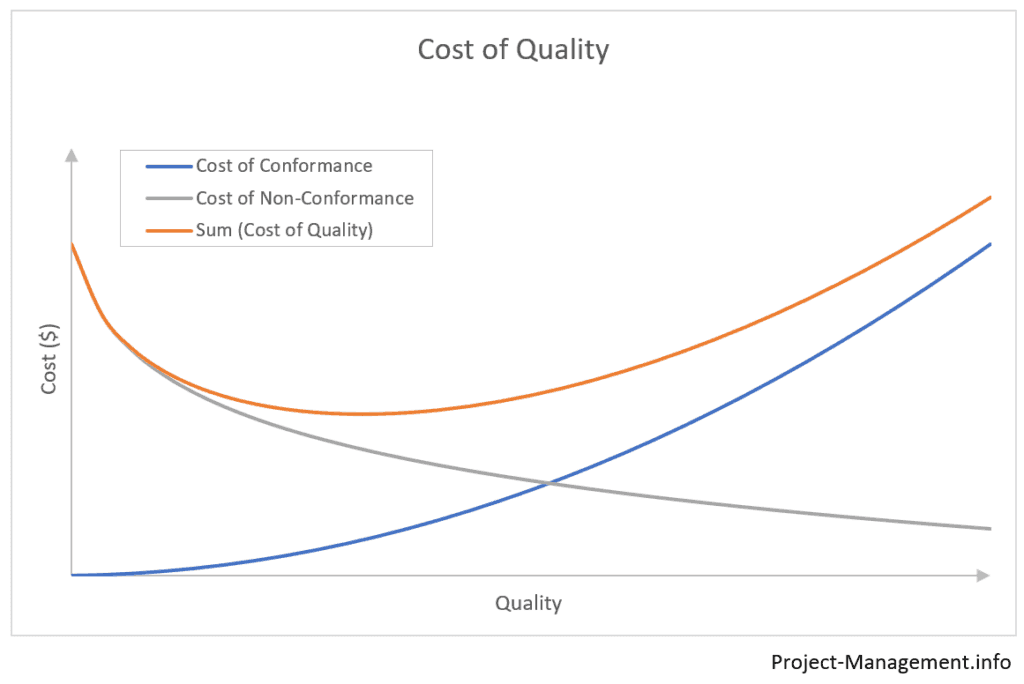

The PMBOK states that COQ is optimized at the point of the smallest sum of cost of conformance and failure costs. The following chart, showing the curves of conformance and non-conformance costs, illustrates that optimization.

his chart shows the cost of conformance and the cost of non-conformance curves. The sum of both curves is the cost of quality (orange line). The lowest point of this curve is the optimized COQ amount which is (theoretically) the level of quality a project should be aiming at.

In other words, the optimum is the point where the costs of quality are the lowest. At that point, any additional Dollar spent on conformance saves non-conformance costs of a Dollar or less, the marginal return would be negative.

In practice, these numbers are hard to compile though, given the unpredictability of certain components, particularly external failure costs. In fact, there are numerous examples of firms failing to get this equation right – refer to the examples of external failure costs mentioned in a previous section.

Nevertheless, the concept of optimizing COQ is relevant for and applied by many projects even though it usually requires some tailoring (source). The following examples illustrate a simple use case of COQ considerations.

Example of Cost of Quality Considerations

This section contains a simplified yet realistic example of cost of quality considerations in an IT project.

Identifying the Cost of Conformance and Non-Conformance

In a Data Warehouse project, a project manager is trying to balance the cost of documenting interfaces and data flows and the expected long-term cost of not doing so.

The estimates are as follows:

- Documenting all changes to the system on a detailed level would require 100 man-days.

- The experience of similar projects shows that a lack of detailed documentation leads to an average additional resource requirement of 30 to 40 man-days per year.

- Even basis documentation would reduce this to annual additional efforts to 5 man-days while detailed documentation would not require any additional efforts.

- The cost of this basis documentation would be 30 man-days for the current project.

- The lifecycle of the IT solution is estimated to be 10 years.

The creation of the documentation is an example of prevention costs (hence part of the cost of conformance). The additional work that will occur in the future to deal with documentation lacks is cost of non-conformance.

The estimates are summarized in the following table based on this classification:

| Cost of Conformance | Cost of Non-Conformance | |

|---|---|---|

| Full documentation | 100 | 0 |

| Basic documentation | 30 | 50 |

| No documentation (min) | 0 | 300 |

| No documentation (max) | 0 | 400 |

Calculating and Interpreting the Cost of Quality

As previously stated, the cost of quality is the sum of conformance and non-conformance costs.

Summing up these costs for each scenario, the cost of quality over the entire lifecycle is as follows:

| Cost of Conformance | Cost of Non-Conformance | Cost of Quality | |

|---|---|---|---|

| Full documentation | 100 | 0 | 100 |

| Basic documentation | 30 | 50 | 80 |

| No documentation (min) | 0 | 300 | 300 |

| No documentation (max) | 0 | 400 | 400 |

The basic documentation would obviously be the best choice in this case. With 80 man-days in total, it has the lowest cost of quality.

A basic documentation requires 30 man-days (cost of conformance) for its creation and 50 man-days cost of non-conformance accumulated over 10 years. The total cost of quality is 80 man-days while the failure cost would be reduced by 250 to 350 man-days throughout the lifecycle of the solution.

The generation of a detailed documentation requires 100 man-days, which would result in 0 costs of non-conformance. Although failure costs of 0 look appealing, the overall cost of quality is higher than the basic documentation scenario (this is an example of the previously mentioned diminishing marginal utility of cost of conformance).

In other words, the detailed documentation would save 300-400 man-days failure costs compared to the ‘no documentation’ scenario over the lifecycle of the data warehouse, but that’s only 50 man-days additional savings compared to the ‘basic documentation’ option.

All in all, the overall benefit of the basic documentation is 220 to 320 man-days (250 and 350, respectively, less 30 man-days for the creation) while the benefit of the detailed documentation would be 200 to 300 man-days (300 to 400 man-days saved for 100 man-days spent).

However, the efforts are incurred during the project (hence subject to the project budget and the project manager’s responsibility) while the benefits of a proper COQ consideration are realized after the project has been completed.

Thus, it becomes clear why these considerations are often assigned to a central PMO or portfolio management (as suggested in the PMBOK) rather than the management of a single project.

Costs of Conformance :

The costs of conformance are ones needed to complete various activities that help the project meet quality requirements and avoid failing. There are two categories under the costs of conformance umbrella: prevention costs and appraisal costs.

(1) Prevention costs- Examples include equipment and maintenance, planning, training, documentation, human resources, quality assurance, process control, etc.

(2) Appraisal costs- Examples include evaluating products and services, completing inspections, field testing, implementing quality control, identifying and fixing defects before products get to market, destroying defective products, etc.

Costs of Non-Conformance :

Less favorable than costs of conformance are costs of non-conformance. If you discover that your products or services are defective after they’ve been on the market, you need to spend money in order to remedy the situation. Therefore, you’re going to incur costs of non-conformance.

Similar to costs of conformance, there are two categories for costs of non-conformance: internal failure costs and external failure costs.

1.Internal Failure Costs:

The company incurs these costs when they identify defects before they reach consumers. For example, if you discover that a product is defective, you need to pay to have it repaired or reworked before shipping it out to customers. Thus, the costs of repairing the defective product are internal failure costs.

2.External Failure Costs:

On the other hand, external failure costs occur after customers receive a defective product or service. Some of these costs include warranty services, complaint handling, product recalls, liability judgments, etc. Unfortunately, external failure costs often lead to loss of your business’ reputation, too.

Prevention is Key!

As a project manager, prevention is of utmost importance. If you can detect problems early on, it’s going to save you time and money. So, to limit the cost of quality, focus on costs of conformance so you don’t incur more costs of non-conformance.

While preparing for the exam, consider the times that you’ve applied these ideas in your profession. Draw from this experience as you prepare to answer cost of quality PMP questions.

Conclusion

Cost of quality is an important concept in both project quality management as well as project cost estimation (it is also a common topic in PMP exams). Finding the right balance between conformance cost and acceptable costs of failure is key to deliver a project with a sustainable success beyond its duration.

However, this is easier said than done. External failure costs are hard to predict. Yet they can have a fatal impact on an organization. In many projects, project goals and budget pressure might incentivize a short-term focus while the potential long-term cost of non-conformance might not receive the ideal amount of management attention. The PMBOK suggests therefore that COQ considerations are done by program management or other organizational units that are responsible for the long-term effects of quality considerations.

Lastly, there’s also another interesting aspect to COQ and project management – the cost of quality of a project itself (rather than its deliverable). When you are managing a project, you might consider using a COQ-like concept with respect to your stakeholder communication and engagement.

Are you looking training with Right Jobs?

Contact Us- Why You Should Do Microsoft Project Certification?

- what is risk management?

- Risk Management Strategies

Related Articles

Popular Courses

- PMP Certification Training

14569 Learners - CAPM Certification Training

12022 Learners - Jira Training

13761 Learners

- What is Dimension Reduction? | Know the techniques

- Difference between Data Lake vs Data Warehouse: A Complete Guide For Beginners with Best Practices

- What is Dimension Reduction? | Know the techniques

- What does the Yield keyword do and How to use Yield in python ? [ OverView ]

- Agile Sprint Planning | Everything You Need to Know