- What is Lean?| Everything You Need to Know

- What is SAP Workflow? : A Complete Guide

- Difference between Tableau and Power BI | Benefits and Special Features

- Data Warehouse in Tableau | Everything You Need to Know

- What is Tableau Server?| Everything You Need to Know | A Definitive Guide

- What is Dax in Power BI? | A Comprehensive Guide

- Upgrade in Tableau Desktop and Web Authoring | A Complete Guide with Best Practices

- What is SAP HANA | SAP HANA Database Connection | All you need to know [ OverView ]

- SAP BPC – What is Business Planning and Consolidation? : All you need to know [ OverView ]

- Root Cause Analysis: Definition, Examples & Methods | All you need to know [ OverView ]

- Seven Basic Quality Improvement Ishikawa Tools | Important asset to control quality in your project [OverView]

- What is Power BI | Its Use Cases and Applications | All you need to know [ OverView ]

- How and why to measure and analyze employee productivity | Everything You Need to Know

- Top 10 Employee Retention Strategies | Everything You Need to Know

- What are LookML Projects and the Developer Mode | How to Create LookML Projects?

- What are Slowly Changing Dimension | SCD Types and Implementations | Step-By-Step Process

- What is Pareto Chart and How to Create Pareto Chart | A Complete Guide For Beginners

- What does an Agile Business Analyst do | Required Skills, Roles and Responsibilities [ Job & Future ]

- What is Lean Management? | Role and Concepts of Lean Management | Expert’s Top Picks

- A Definitive Guide of Working Capital Management with Best Practices & REAL-TIME Examples

- Business Analytics with Excel Fundamentals | A Complete Guide For Beginners

- Business Analyst : Job Description | All you need to know [ Job & Future ]

- How to create a Splunk Dashboard | A Complete Guide For Beginners [ OverView ]

- What is Splunk Logging ? | The Ultimate Guide with Expert’s Top Picks

- Alteryx vs Tableau | Know Their Differences and Which Should You Learn?

- What is Predictive Analytics? : Step-By-Step Process with REAL-TIME Examples

- An Overview of SAS Stored Processes | The Ultimate Guide with Expert’s Top Picks

- How to Create Conditional Formatting in Cognos Report Studio | A Complete Guide

- Difference between OLTP vs OLAP | Know Their Differences and Which Should You Learn?

- ECBA vs CCBA vs CBAP | A Complete Guide For Beginners | Know Their Differences and Which Should You Learn?

- Import Custom Geocode Data in Tableau | Everything You Need to Know [ OverView ]

- Data Warehouse Tools : Features , Concepts and Architecture

- PGDM vs MBA | Know Their Differences and Which Should You Learn?

- Most Popular Data Visualization Tools | A Complete Beginners Guide | REAL-TIME Examples

- Tableau vs Looker : Comparision and Differences | Which Should You Learn?

- Benefits of Employee Satisfaction for the Organization [ Explained ]

- DAX In Power BI – Learn Power BI DAX Basics [ For Freshers and Experience ]

- Power Bi vs Tableau : Comparision and Differences | Which Should You Learn?

- What is Alteryx Tools | Alteryx ETL Tools | Comprehensive Guide

- What is Tableau Prep? : Comprehensive Guide | Free Guide Tutorial & REAL-TIME Examples

- What are Business Intelligence Tools ? : All you need to know [ OverView ]

- Tableau Aggregate Functions | A Complete Guide with REAL-TIME Examples

- Intervalmatch Function in Qlikview | Everything You Need to Know [ OverView ]

- QlikView Circular Reference | Free Guide Tutorial & REAL-TIME Examples

- Data Blending in Tableau | A Complete Guide with Best Practices | Free Guide Tutorial [ OverView ]

- Splunk vs ELK | Differences and Which Should You Learn? [ OverView ]

- QlikSense vs QlikView | Differences and What to learn and Why?

- What Is Measurement System Analysis | Required Skills | Everything You Need to Know

- Splunk Timechart | Free Guide Tutorial & REAL-TIME Examples

- What Is Image Processing ? A Complete Guide with Best Practices

- What is a Business Analysis ? A Complete Guide with Best Practices

- Top Business Analytics Tools | Comprehensive Guide

- Business Analyst Career Path [ Job & Future ]

- Time Series Analysis Tactics | A Complete Guide with Best Practices

- What is Splunk ? Free Guide Tutorial & REAL-TIME Examples

- Which Certification is Right for You: Six Sigma or Lean Six Sigma?

- SAS Vs R

- Top Technology Trends for 2020

- Data Analyst vs. Data Scientist

- What are the Essential Skills That You Need to Master in Data Analyst?

- What is Six Sigma?

- Common Cause Variation Vs Special Cause Variation

- Reasons to Get a Six Sigma Certification

- What Is Strategic Enterprise Management and its Components?

- What Are The Benefits Measurement Constrained Optimization Methods?

- What Is the Benefit of Modern Data Warehousing?

- What Is Corporate Social Responsibility (CSR)?

- What Is The Purpose and Importance Of Financial Analysis?

- What is Insights-as-a-Service (IaaS)?

- Business Analytics With R Programming Languages

- Where Are The 8 Hidden Wastes?

- What Are Market Structures?

- What is Cost of Quality (COQ)?

- What is Build Verification Testing?

- Quality Improvement in Six Sigma

- What is Process Capability Analysis?

- How To Measure The Effectiveness Of Corporate Training

- SAP Financials And SAP Accounting Modules

- Tips to Learn Tableau

- Why Should I Become a CBAP?

- History And Evolution of Six Sigma

- How to use Control Chart Constants?

- Data Analytics Course For Beginners

- How to Build a Successful Data Analyst Career?

- Data Analytics Vs Business Analytics

- What is SAP Certification?

- Books To Read For a Six Sigma Certification

- Six Sigma Green Belt Salary

- What is the ASAP Methodology?

- Complete list of SAP modules

- What is Lean?| Everything You Need to Know

- What is SAP Workflow? : A Complete Guide

- Difference between Tableau and Power BI | Benefits and Special Features

- Data Warehouse in Tableau | Everything You Need to Know

- What is Tableau Server?| Everything You Need to Know | A Definitive Guide

- What is Dax in Power BI? | A Comprehensive Guide

- Upgrade in Tableau Desktop and Web Authoring | A Complete Guide with Best Practices

- What is SAP HANA | SAP HANA Database Connection | All you need to know [ OverView ]

- SAP BPC – What is Business Planning and Consolidation? : All you need to know [ OverView ]

- Root Cause Analysis: Definition, Examples & Methods | All you need to know [ OverView ]

- Seven Basic Quality Improvement Ishikawa Tools | Important asset to control quality in your project [OverView]

- What is Power BI | Its Use Cases and Applications | All you need to know [ OverView ]

- How and why to measure and analyze employee productivity | Everything You Need to Know

- Top 10 Employee Retention Strategies | Everything You Need to Know

- What are LookML Projects and the Developer Mode | How to Create LookML Projects?

- What are Slowly Changing Dimension | SCD Types and Implementations | Step-By-Step Process

- What is Pareto Chart and How to Create Pareto Chart | A Complete Guide For Beginners

- What does an Agile Business Analyst do | Required Skills, Roles and Responsibilities [ Job & Future ]

- What is Lean Management? | Role and Concepts of Lean Management | Expert’s Top Picks

- A Definitive Guide of Working Capital Management with Best Practices & REAL-TIME Examples

- Business Analytics with Excel Fundamentals | A Complete Guide For Beginners

- Business Analyst : Job Description | All you need to know [ Job & Future ]

- How to create a Splunk Dashboard | A Complete Guide For Beginners [ OverView ]

- What is Splunk Logging ? | The Ultimate Guide with Expert’s Top Picks

- Alteryx vs Tableau | Know Their Differences and Which Should You Learn?

- What is Predictive Analytics? : Step-By-Step Process with REAL-TIME Examples

- An Overview of SAS Stored Processes | The Ultimate Guide with Expert’s Top Picks

- How to Create Conditional Formatting in Cognos Report Studio | A Complete Guide

- Difference between OLTP vs OLAP | Know Their Differences and Which Should You Learn?

- ECBA vs CCBA vs CBAP | A Complete Guide For Beginners | Know Their Differences and Which Should You Learn?

- Import Custom Geocode Data in Tableau | Everything You Need to Know [ OverView ]

- Data Warehouse Tools : Features , Concepts and Architecture

- PGDM vs MBA | Know Their Differences and Which Should You Learn?

- Most Popular Data Visualization Tools | A Complete Beginners Guide | REAL-TIME Examples

- Tableau vs Looker : Comparision and Differences | Which Should You Learn?

- Benefits of Employee Satisfaction for the Organization [ Explained ]

- DAX In Power BI – Learn Power BI DAX Basics [ For Freshers and Experience ]

- Power Bi vs Tableau : Comparision and Differences | Which Should You Learn?

- What is Alteryx Tools | Alteryx ETL Tools | Comprehensive Guide

- What is Tableau Prep? : Comprehensive Guide | Free Guide Tutorial & REAL-TIME Examples

- What are Business Intelligence Tools ? : All you need to know [ OverView ]

- Tableau Aggregate Functions | A Complete Guide with REAL-TIME Examples

- Intervalmatch Function in Qlikview | Everything You Need to Know [ OverView ]

- QlikView Circular Reference | Free Guide Tutorial & REAL-TIME Examples

- Data Blending in Tableau | A Complete Guide with Best Practices | Free Guide Tutorial [ OverView ]

- Splunk vs ELK | Differences and Which Should You Learn? [ OverView ]

- QlikSense vs QlikView | Differences and What to learn and Why?

- What Is Measurement System Analysis | Required Skills | Everything You Need to Know

- Splunk Timechart | Free Guide Tutorial & REAL-TIME Examples

- What Is Image Processing ? A Complete Guide with Best Practices

- What is a Business Analysis ? A Complete Guide with Best Practices

- Top Business Analytics Tools | Comprehensive Guide

- Business Analyst Career Path [ Job & Future ]

- Time Series Analysis Tactics | A Complete Guide with Best Practices

- What is Splunk ? Free Guide Tutorial & REAL-TIME Examples

- Which Certification is Right for You: Six Sigma or Lean Six Sigma?

- SAS Vs R

- Top Technology Trends for 2020

- Data Analyst vs. Data Scientist

- What are the Essential Skills That You Need to Master in Data Analyst?

- What is Six Sigma?

- Common Cause Variation Vs Special Cause Variation

- Reasons to Get a Six Sigma Certification

- What Is Strategic Enterprise Management and its Components?

- What Are The Benefits Measurement Constrained Optimization Methods?

- What Is the Benefit of Modern Data Warehousing?

- What Is Corporate Social Responsibility (CSR)?

- What Is The Purpose and Importance Of Financial Analysis?

- What is Insights-as-a-Service (IaaS)?

- Business Analytics With R Programming Languages

- Where Are The 8 Hidden Wastes?

- What Are Market Structures?

- What is Cost of Quality (COQ)?

- What is Build Verification Testing?

- Quality Improvement in Six Sigma

- What is Process Capability Analysis?

- How To Measure The Effectiveness Of Corporate Training

- SAP Financials And SAP Accounting Modules

- Tips to Learn Tableau

- Why Should I Become a CBAP?

- History And Evolution of Six Sigma

- How to use Control Chart Constants?

- Data Analytics Course For Beginners

- How to Build a Successful Data Analyst Career?

- Data Analytics Vs Business Analytics

- What is SAP Certification?

- Books To Read For a Six Sigma Certification

- Six Sigma Green Belt Salary

- What is the ASAP Methodology?

- Complete list of SAP modules

How to use Control Chart Constants?

Last updated on 01st Oct 2020, Artciles, Blog, Business Analytics

How to use Control Chart Constants?

CONTROL CHARTS

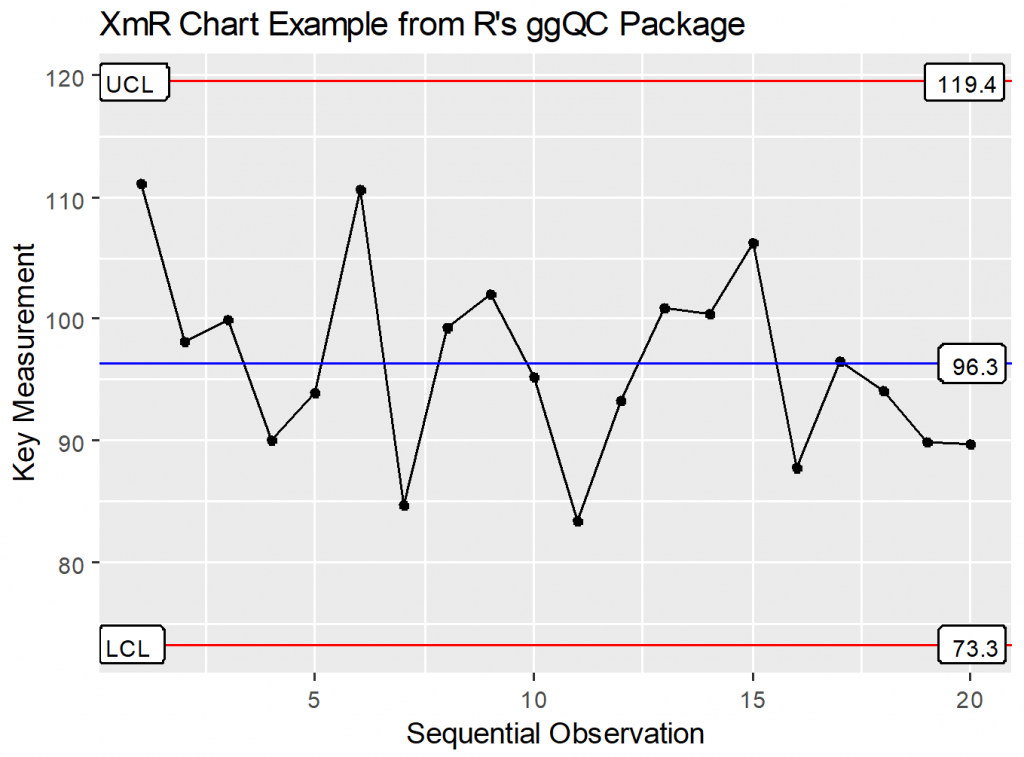

Control chart constants are the engine behind charts such as XmR, XbarR, and XbarS. And, if you’ve made a control chart by hand or sat in a class, you’ll likely have memories of bizarre constants like d2, A2, etc. To me, control chart constants are a necessary evil. Why? Because, it’s a nuisance to look up a constant to make a chart, and I suspect that has likely frightened away many would be users over the years. These days though, if you have a good piece of statistical software you won’t even see these numbers. Open source options include R’s ggQC package. An example plot is shown below. Other open source options include qcc, iqcc, and qicharts to name a few.

Subscribe For Free Demo

Error: Contact form not found.

There are also commercially available options like minitab or JMP. Regardless of the available software, it’s still good to have a place to find these numbers when you need them and a quick explanation of their use. It’s also nice to have a sense of what these numbers physically mean.

In the next few sections, you’ll see in brief how we change quantities such as mean moving range (mR), mean range, and mean standard deviation into dispersion statistics using the control chart constants. With that dispersion statistic in hand, we can calculate control limits for our data. To begin, we’ll start with the building blocks – the bias correction factors.

Bias Correction Control Chart Constants

Bias correction constants are the fundamental quantities that allow you to calculate other higher level control constants such as A2, D3, D4, etc. Subsequent sections provide examples of how these constants are calculated.

To get a better grasp of what the bias correction factors are see my article on Estimating Control Chart Constants. There, I’ll walk you through the math and simulation to pull it all together.

Bias Correction Constants

| n | d2 | c4 | d3 | d4 |

|---|---|---|---|---|

| 2 | 1.1284 | 0.7979 | 0.8525 | 0.9539 |

| 3 | 1.6926 | 0.8862 | 0.8884 | 1.5878 |

| 4 | 2.0588 | 0.9213 | 0.8798 | 1.9783 |

| 5 | 2.3259 | 0.9400 | 0.8641 | 2.2569 |

| 6 | 2.5344 | 0.9515 | 0.8480 | 2.4717 |

XmR Control Chart Constants

XmR Constants

| n | d2 | d3 | D4 |

|---|---|---|---|

| 2 | 1.1284 | 0.8525 | 3.2665 |

XmR Chart Calculation Reference

1.Find the center line by calculating the mean of your data points

X = mean(data)

2.Determine the mean moving range of your data points. Data must be in the sequence the samples were produced.

mR = mean(mR)

3.Convert mean(mR) to sequential deviation(Š):

Š = mR/ d2 = mR / 1.128

4.Calculate the upper and lower XmR control limits using the sequential deviation

- Lower XmR Control Limit(LCL): LCLX = X – 3 ⋅ Š

- Upper XmR Control Limit(UCL): UCLX = X + 3 ⋅ Š

mR Chart Calculations

Find the center line by calculating the mean moving range of your data points. Data must be in the sequence the samples were produced.

mR = mean(mR)

1.Calculate the upper and lower mR control limits

2.mR Lower Control Limit: LCLmR = 0

3.mR Upper Control Limit: UCLmR = 1 + 3(d3 / d2) ⋅ mR = D4 ⋅ mR

Additional XmR Constant Information

- The constant 2.66 is sometimes used to calculate XmR chart limits. The constant takes into account the 3 used to calculate the upper and lower control limit.

2.66 = 3 / d2 = 3 / 1.12838 - Using the 2,66 constant

Control Limits = X ± 2.66 ⋅ mR - The D4 constant is a function of d2 and d3:

D4 = 1 + 3(d3 / d2) = 3.2665

XbarR Control Chart Constants

XbarR charts are useful when you have sub-groups. For example:

- You have a very precise process for making cupcakes that uses a pan that can make 12 at a time. After cooking, you measure the weight of each cupcake to make sure the batter was evenly distributed. Here, the sub-group size = 12

- You have a measurement process where you make 5 measurements of a reference standard daily. Here, the subgroup size = 5

XbarR Constants

| d2 | d3 | A2 | D3 | D4 |

|---|---|---|---|---|

| 1.1284 | 0.8525 | 1.8800 | 0.0000 | 3.2665 |

| 1.6926 | 0.8884 | 1.0233 | 0.0000 | 2.5746 |

| 2.0588 | 0.8798 | 0.7286 | 0.0000 | 2.2821 |

| 2.3259 | 0.8641 | 0.5768 | 0.0000 | 2.1145 |

| 2.5344 | 0.8480 | 0.4832 | 0.0000 | 2.0038 |

XbarR Chart Calculation Reference

1.Determine the subgroup size: n

2.Calculate the mean of each sub-group:

X = mean(each sub-group)

3.Find the center line by calculating the mean of all sub-group means:

X̿ = mean(mean(each sub-group))

4.Determine the range, Max(value)-Min(Value), for each sub-group:

R = range(each sub-group)

5.Calculate the mean range of all sub-group ranges:

R = mean(range(each sub-group))

6.Convert mean of mean ranges to within deviation, Wd:

Wd = R / d2n

- Example 1: If n = 3 then Wd = R / 1.693

- Example 2: If n = 10 then Wd = R / 3.078

7.Determine your Upper and Lower Control Limits: Natural or Studentized

- Natural Control Limits will give you the window for the individual measurements in your process.

- Lower XbarR Natural Control Limit: LNCLx = X̿ – (3 ⋅ Wd) / √ 1

- Upper XbarR Natural Control Limit: UNCLx = X̿ + (3 ⋅ Wd) / √ 1

- Note: The natural limits use the √ 1 and studentized limits use √ n (see below). It’s akin to the difference between standard deviation(SD) and standard error (SD / √ n )

- Studentized Control Limits (method 1) will give you the window for sub-group means.

- Lower XbarR Studentized Control Limit:LCLx = X̿ – (3 ⋅ Wd) / √ n

- Upper XbarR Studentized Control Limit:UCLx = X̿ + (3 ⋅ Wd) / √ n

- Studentized Control Limits (method 2) will give you the window for sub-group means using the control constant A2.

- A2n = 3 / (d2n ⋅ √ n )

- A2n = 3 / (d2n ⋅ √ n )

- Lower XbarR Studentized Control Limit: LCLx = X̿ – R ⋅ A2n

- Upper XbarR Studentized Control Limit: UCLx = X̿ + R ⋅ A2n

Quick Demonstration: Let’s show that method 1 and 2 for calculating the control limits yields the same result.

Suppose n = 3; X̿ = 5, R = 7.

Method 1:

For n = 3, d2 = 1.6926, Wd = 7 / 1.6926 = 4.1356

LCLx = 5 – 3 ⋅ 4.1356 / √ 3 = -2.163

UCLx = 5 + 3 ⋅ 4.1356 / √ 3 = 12.163

Method 2:

For n = 3, A2 = 1.0233,

LCLx = 5 – 7 ⋅ 1.0233 = -2.163

LCLx = 5 + 7 ⋅ 1.0233 = 12.163

The Point:

For a given sub-group size = n:

A2n = 3 / (d2n ⋅ √ n )

R Chart Calculations

- Determine the subgroup size: n

- Calculate the range, Max(value)-Min(Value), for each sub-group:

R = range(each sub-group) - Determine the center line by calculating the mean range of all sub-group ranges:

R = mean(range(each sub-group)) - Find R chart control limits:

- R Lower Control Limit: LCLR = D3 ⋅ R

- R Upper Control Limit:UCLR = D4 ⋅ R

Additional R Chart Constant Information

- The D3 constant is a function of d2, d3, and n.

If n = 5 Then

D3n=5 = 1 – 3(d3n=5 / d2n=5) = -0.1145 → 0 - The D4 constant is a function of d2, d3, and n.

If n = 5 Then

D4n=5 = 1 + 3(d3n=5 / d2n=5) = 2.1145

XbarS Control Chart Constants

XbarS charts come into play when you have sub-groups. For example:

- You have a very precise process for making cupcakes that uses a pan that can make 12 at a time. After cooking, you measure the weight of each cupcake to make sure the batter was evenly distributed. Here, the sub-group size = 12

- You have a measurement process where you make 5 measurements of a reference standard daily. Here, the subgroup size = 5

XbarS charts can be made with ggQC using method = “xBar.sBar”.

XbarS Constants

| n | c4 | A3 | B3 | B4 |

|---|---|---|---|---|

| 2 | 0.7979 | 2.6587 | 0.0000 | 3.2665 |

| 3 | 0.8862 | 1.9544 | 0.0000 | 2.5682 |

| 4 | 0.9213 | 1.6281 | 0.0000 | 2.2660 |

| 5 | 0.9400 | 1.4273 | 0.0000 | 2.0890 |

| 6 | 0.9515 | 1.2871 | 0.0304 | 1.9696 |

XbarS Chart Calculation Reference

1.Determine the subgroup size: n

2.Calculate the mean of each sub-group: X = mean(each sub-group)

3.Find the center line by calculating the mean of all sub-group means:

X̿ = mean(mean(each sub-group))

4.Determine the standard deviation for each sub-group:

S = sd(each sub-group)

5.Calculate the mean of all sub-group standard deviations:

S = mean(sd(each sub-group))

6.Convert mean subgroup standard deviation to within deviation, Wd:

Wd = S / c4n

- Example 1: If n = 3 then Wd = S / 0.8862

- Example 2: If n = 10 then Wd = S / 0.9727

7.Determine your Upper and Lower Control Limits: Natural or Studentized

- Natural Control Limits will give you the window for the individual measurements in your process.

- Lower XbarS Natural Control Limit:

LNCLx = X̿ – (3 ⋅ Wd) / √ 1 - Upper XbarS Natural Control Limit:

UNCLx = X̿ + (3 ⋅ Wd) / √ 1

- Lower XbarS Natural Control Limit:

- Note: The natural limits use the √ 1 and studentized limits use √ n (see below). It’s akin to the difference between standard deviation(SD) and standard error (SD / √ n )

- Studentized Control Limits (method 1) will give you the window for sub-group means.

- Lower XbarS Studentized Control Limit:

LCLx = X̿ – (3 ⋅ Wd) / √ n - Upper XbarS Studentized Control Limit:

UCLx = X̿ + (3 ⋅ Wd) / √ n

- Lower XbarS Studentized Control Limit:

- Studentized Control Limits (method 2) will give you the window for sub-group means using the control constant A3.

- A3n = 3 / (c4n ⋅ √ n )

- Lower XbarS Studentized Control Limit:

LCLx = X̿ – S ⋅ A3n - Upper XbarS Studentized Control Limit:

UCLx = X̿ + S ⋅ A3n

Quick Demonstration: Let’s show that method 1 and 2 for calculating the control limits yields the same result.

Suppose n = 3; X̿ = 5, S = 2.

Method 1:

For n = 3, c4 = 0.8862, Wd = 2 / 0.8862 = 2.2568

LCLx = 5 – 3 ⋅ 2.2568 / √ 3 = 1.091

UCLx = 5 + 3 ⋅ 2.2568 / √ 3 = 8.909

Method 2:

For n = 3, A3 = 1.954,

LCLx = 5 – 2 ⋅ 1.0233 = 1.092

LCLx = 5 + 2 ⋅ 1.0233 = 8.908

The Point:

For a given sub-group size = n:

A3n = 3 / (c4n ⋅ √ n )

S Chart Calculations

1. Determine the subgroup size: n

2.Determine the standard deviation for each sub-group:

S = sd(each sub-group)

3.Calculate the mean of all sub-group standard deviations:

S = mean(sd(each sub-group))

4.Find S chart control limits:

- S Lower Control Limit:LCLS = B3 ⋅ S

- S Upper Control Limit:UCLS = B4 ⋅ S

Additional S Chart Constant Information

- The B3 constant is a function of c4 and n.

If n = 5 then

B3n=5 = 1 – 3 / c4n=5 ⋅ (√ 1 – (c4)² ) = -0.0889 → 0 - The B4 constant is a function of c4 and n.

If n = 5 then

B4n=5 = 1 + 3 / c4n=5 ⋅ (√ 1 – (c4)² ) = 2.0889

Summary

Tables of control chart constants and a brief explanation of how control chart constants are used in different contexts has been presented. XmR, XbarR, XbarS, mR, R, and S type control charts all require these constants to determine control limits appropriately. For XmR charts, there is only one constant needed to determine the control limits for individual observations, 1.128. However for Xbar and XbarS charts, the control constant changes as a function of sub-group size. In addition when you are calculating limits for XbarR or XbarS charts, you need to know if you are calculating natural control limits for individual measurements or studentized control limits for sub-group means. If you are doing the calculations by hand, use method 1 described above to help keep the difference between individual and studentized straight.