What is Lean Management? : A Complete Guide

Last updated on 30th Jan 2023, Artciles, Blog

- In this article you will learn:

- 1.Introduction to Lean Management.

- 2.History of Lean Management.

- 3.Principles of Lean Management.

- 4.Benefits of Lean Management.

- 5.Conclusion.

Introduction to a Lean Management:

Lean management is a business practise that aims to improve quality and efficiency by removing wasteful resources such as time, money and effort.It is often referred to as lean manufacturing or lean production.The goal is to provide only the greatest and most value services or goods to consumers and clients at the best possible price.

History of Lean Management:

- The concept of a lean management originated in a Japanese manufacturing industry in 1990s beginning with Toyota Production System (TPS).

- Because Toyota was initially small automobile manufacturer that are eventually became successful on global scale, it’s business and operational process quickly caught on.

- The Other companies soon began to adopt a similar methodologies with hope of achieving a same level of success.

- Today lean management is widely used by a leading businesses around world, including Intel, John Deere and Nike.

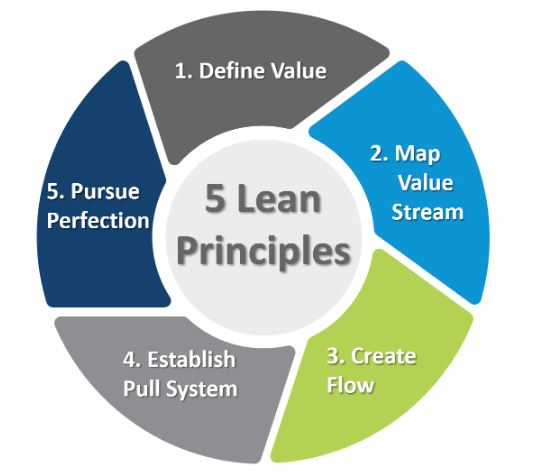

Principles of Lean Management:

Lean management revolves the around these core principles explaining a value mapping stream value creating flow establishing pull and pursuing perfection:

Defining Value :

- This principle identifies a value of a product or service from a customer’s perspective.

- Rotating Solutions are highlights importance of creating and focusing on timeline for a production process including delivery.

- This can include the detailing crucial requirements, price points, expectations and the other essential information.

Mapping Stream Value:

This principle is also known as a waste mapping.It examines all the steps of any given business process to find which unnecessary actions and resources can be eliminated to maximize the efficiency.

Creating Flow :

This principle focuses on be attaining an efficiency and speed as well as also ensuring that a multiple operational tasks are completed as quickly and smoothly as possible without sacrificing quality.

Establishing Pull:

Create flow in which there are just enough materials and resources to create a required products on a time and in a continuous fashion.

Pursuing Perfection :

Really this means making a sure that the other four principles occur be continuously and consistently.Make sure all an employees are also on board with ultimate lean mission.Another way to look at a lean management is through a following five stages that complement a general principles. Known as a “5S” and translated from a Japanese they include:

- Seiri (organization)

- Seiton (order)

- Seiso (cleanliness)

- Seiketsu (standardization)

- Shitsuke (discipline)

Benefits of a Lean Management:

- They can also promote client satisfaction which can lead to greater income from recommendations and repeat business.

- Furthermore getting adept in lean management might be a worthwhile investment.

- The Lean Management Certification Training programme offers students critical lean management skills that will not only benefit them in their present work but will also help them be successful in future chances.

- In this training program students learn about all the aspects of lean management and how these principles can be applied in a services, manufacturing and also general business roles.

- Students learn about a various tools in a lean management, common types of waste and ways to eliminate it to improve the overall business efficiency.

- Students enrolled in this course receive a five hours of e-learning content a downloadable e-book and the other resources that are useful for all the skill levels. Once completed students earn lean management certification.

Conclusion:

Lean management is beneficial to more organizations for their growth and providing a solutions to their customers actual problems. Can provide a real value to customers because a main focus is a resource optimization. Lean methodology principles enable a teams to create stable workflows based on a actual demands from the customers. Therefore can conclude that a ultimate goal of Lean is be continuous improvement. Each employee is involved in an improvement process.

Are you looking training with Right Jobs?

Contact Us- The Impact of AI and Machine Learning on Cybersecurity | Everything You Need to Know

- Open Datasets for Machine Learning | A Complete Guide For Beginners with Best Practices

- What is a Confusion Matrix in Machine Learning? : A Complete Guide For Beginners

- Bagging vs Boosting in Machine Learning | Know Their Differences

- Difference between Artificial Intelligence and Machine Learning | Everything You Need to Know

Related Articles

Popular Courses

- Hadoop Developer Training

11025 Learners - Apache Spark With Scala Training

12022 Learners - Apache Storm Training

11141 Learners

- What is Dimension Reduction? | Know the techniques

- Difference between Data Lake vs Data Warehouse: A Complete Guide For Beginners with Best Practices

- What is Dimension Reduction? | Know the techniques

- What does the Yield keyword do and How to use Yield in python ? [ OverView ]

- Agile Sprint Planning | Everything You Need to Know