ROBOTICS Tutorial

Last updated on 19th Sep 2020, Blog, Tutorials

Roboticists develop man-made mechanical devices that can move by themselves, whose motion must be modelled, planned, sensed, actuated and controlled, and whose motion behaviour can be influenced by programming. Robots are called intelligent if they succeed in moving in safe interaction with an unstructured environment, while autonomously achieving their specified tasks.

This definition implies that a device can only be called a robot if it contains a movable mechanism, influenced by sensing, planning, actuation and control components. It does not imply that a minimum number of these components must be implemented in software, or be changeable by the consumer who uses the device; for example, the motion behaviour can have been hard-wired into the device by the manufacturer.

So, the presented definition, as well as the rest of the material in this part of the WEBook, covers not just pure robotics or only intelligent robots, but rather the somewhat broader domain of robotics and automation. This includes dumb robots such as: metal and woodworking machines, intelligent washing machines, dish washers and pool cleaning robots, etc. These examples all have sensing, planning and control, but often not in individually separated components. For example, the sensing and planning behaviour of the pool cleaning robot have been integrated into the mechanical design of the device, by the intelligence of the human developer.

Robotics is, to a very large extent, all about system integration, achieving a task by an actuated mechanical device, via an intelligent integration of components, many of which it shares with other domains, such as systems and control, computer science, character animation, machine design, computer vision, artificial intelligence, cognitive science, biomechanics, etc. In addition, the boundaries of robotics cannot be clearly defined, since also its core ideas, concepts and algorithms are being applied in an ever increasing number of external applications, and, vice versa, core technology from other domains (vision, biology, cognitive science or biomechanics, for example) are becoming crucial components in more and more modern robotic systems.

This part makes an effort to define what exactly is that above-mentioned core material of the robotics domain, and to describe it in a consistent and motivated structure. Nevertheless, this chosen structure is only one of the many possible views that one can want to have on the robotics domain.

What Is Robotics?

Robotics is the intersection of science, engineering and technology that produces machines, called robots, that substitute for (or replicate) human actions. Pop culture has always been fascinated with robots. R2-D2. Optimus Prime. WALL-E. These over-exaggerated, humanoid concepts of robots usually seem like a caricature of the real thing…or are they more forward thinking than we realize? Robots are gaining intellectual and mechanical capabilities that don’t put the possibility of a R2-D2-like machine out of reach in the future.

As technology progresses, so too does the scope of what is considered robotics. In 2005, 90% of all robots could be found assembling cars in automotive factories. These robots consist mainly of mechanical arms tasked with welding or screwing on certain parts of a car. Today, we’re seeing an evolved and expanded definition of robotics that includes the development, creation and use of bots that explore Earth’s harshest conditions, robots that assist law-enforcement and even robots that assist in almost every facet of healthcare.

While the overall world of robotics is expanding, a robot has some consistent characteristics:

- 1. Robots all consist of some sort of mechanical construction. The mechanical aspect of a robot helps it complete tasks in the environment for which it’s designed. For example, the Mars 2020 Rover’s wheels are individually motorized and made of titanium tubing that help it firmly grip the harsh terrain of the red planet.

- 2. Robots need electrical components that control and power the machinery. Essentially, an electric current (a battery, for example) is needed to power a large majority of robots.

- 3. Robots contain at least some level of computer programming. Without a set of code telling it what to do, a robot would just be another piece of simple machinery. Inserting a program into a robot gives it the ability to know when and how to carry out a task.

Subscribe For Free Demo

Error: Contact form not found.

Components of robotic systems

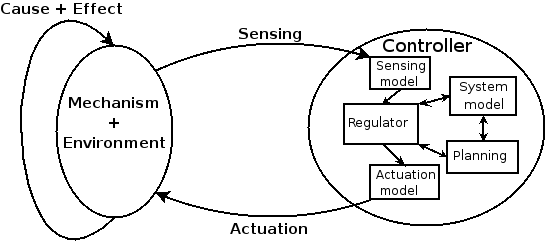

The below figure depicts the components that are part of all robotic systems. The purpose of this Section is to describe the semantics of the terminology used to classify the chapters in the WEBook: sensing, planning, modelling, control, etc.

The real robot is some mechanical device (mechanism) that moves around in the environment, and, in doing so, physically interacts with this environment. This interaction involves the exchange of physical energy, in some form or another. Both the robot mechanism and the environment can be the cause of the physical interaction through Actuation, or experience the effect of the interaction, which can be measured through Sensing.

Laws of Robotics

Asimov proposed three “Laws of Robotics ” and later added the “zeroth law ”

- Law 0: A robot may not injure humanity or through inaction, allow humanity to come to harm

- Law 1: A robot may not injure a human being or through inaction, allow a human being to come to harm, unless this would violate a higher order law

- Law 2: A robot must obey orders given to it by human beings, except where such orders would conflict with a higher order law

- Law 3: A robot must protect its own existence as long as such protection does not conflict with a higher order law

The First Robot: ‘Unimate’

After the technology explosion during World War II, in 1956, a historic meeting occurred between George C. Devol, a successful inventor and entrepreneur, and engineer Joseph F. Engelberger, over cocktails the two discussed the writings of Isaac Asimov. Together they made a serious and commercially successful effort to develop a real, working robot. They persuaded Norman Schafler of Condec Corporation in Danbury that they had the basis of a commercial success. Engelberger started a manufacturing company ‘Unimation’ which stood for universal automation and so the first commercial company to make robots was formed. Devol wrote the necessary patents. Their first robot was nicknamed the ‘Unimate’. As a result, Engelberger has been called the ‘father of robotics.’ The first Unimate was installed at a General Motors plant to work with heated die-casting machines. In fact most Unimates were sold to extract die castings from die casting machines and to perform spot welding on auto bodies, both tasks being particularly hateful jobs for people. Both applications were commercially successful, i.e., the robots worked reliably and saved money by replacing people. An industry was spawned and a variety of other tasks were also performed by robots, such as loading and unloading machine tools. Ultimately Westinghouse acquired Unimation and the entrepreneurs’ dream of wealth was achieved. Unimation is still in production today, with robots for sale. The robot idea was hyped to the skies and became high fashion in the Boardroom. Presidents of large corporations bought them, for about $100,000 each, just to put into laboratories to “see what they could do;” in fact these sales constituted a large part of the robot market. Some companies even reduced their ROI (Return On Investment criteria for investment) for robots to encourage their use.

Modern Industrial Robots

The image of the “electronic brain” as the principal part of the robot was pervasive. Computer scientists were put in charge of robot departments of robot customers and of factories of robot makers. Many of these people knew little about machinery or manufacturing but assumed that they did. (There is a common delusion of electrical engineers that mechanical phenomena are simple because they are visible. Variable friction, the effects of burrs, minimum and redundant constraints, nonlinearities, variations in work pieces, accommodation to hostile environments and hostile people, etc. are like the “Purloined Letter” in Poe’s story, right in front of the eye, yet unseen.) They also had little training in the industrial engineer’s realm of material handling, manufacturing processes, manufacturing economics and human behavior in factories. As a result, many of the experimental tasks in those laboratories were made to fit their robot’s capabilities but had little to do with the real tasks of the factory. Modern industrial arms have increased in capability and performance through controller and language development, improved mechanisms, sensing, and drive systems. In the early to mid 80’s the robot industry grew very fast primarily due to large investments by the automotive industry. The quick leap into the factory of the future turned into a plunge when the integration and economic viability of these efforts proved disastrous. The robot industry has only recently recovered to mid-80’s revenue levels. In the meantime there has been an enormous shakeout in the robot industry. In the US, for example, only one US company, Adept, remains in the production industrial robot arm business. Most of the rest went under, consolidated, or were sold to European and Japanese companies. In the research community the first automata were probably Grey Walter’s machina (1940’s) and the John’s Hopkins beast. Teleoperated or remote controlled devices had been built even earlier with at least the first radio controlled vehicles built by Nikola Tesla in the 1890’s. Tesla is better known as the inventor of the induction motor, AC power transmission, and numerous other electrical devices. Tesla had also envisioned smart mechanisms that were as capable as humans. An excellent biography of Tesla is Margaret Cheney’s Tesla, Man Out of Time, Published by Prentice-Hall, c1981. SRI’s Shakey navigated highly structured indoor environments in the late 60’s and Moravec’s Stanford Cart was the first to attempt natural outdoor scenes in the late 70’s. From that time there has been a proliferation of work in autonomous driving machines that cruise at highway speeds and navigate outdoor terrains in commercial applications. Fully functioning androids (robots that look like human beings) are many years away due to the many problems that must be solved. However, real, working, sophisticated robots are in use today and they are revolutionizing the workplace. These robots do not resemble the romantic android concept of robots. They are industrial manipulators and are really computer controlled “arms and hands”. Industrial robots are so different to the popular image that it would be easy for the average person not to recognize one.

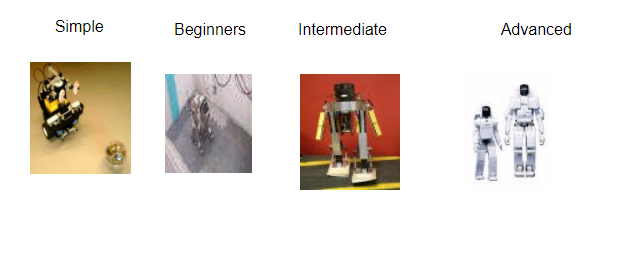

Everything you need to know to get into robotics is here, from motors to programming, the tutorials are organised by difficulty or subject matter.

Types of Robots

Mechanical bots come in all shapes and sizes to efficiently carry out the task for which they are designed. From the 0.2 millimeter-long “RoboBee” to the 200 meter-long robotic shipping vessel “Vindskip,” robots are emerging to carry out tasks that humans simply can’t. Generally, there are five types of robots:

Pre-Programmed Robots

Pre-programmed robots operate in a controlled environment where they do simple, monotonous tasks. An example of a pre-programmed robot would be a mechanical arm on an automotive assembly line. The arm serves one function — to weld a door on, to insert a certain part into the engine, etc. — and it’s job is to perform that task longer, faster and more efficiently than a human.

Humanoid Robots

Humanoid robots are robots that look like and/or mimic human behavior. These robots usually perform human-like activities (like running, jumping and carrying objects), and are sometimes designed to look like us, even having human faces and expressions. Two of the most prominent examples of humanoid robots are Hanson Robotics’ Sophia and Boston Dynamics’ Atlas.

Autonomous Robots

Autonomous robots operate independently of human operators. These robots are usually designed to carry out tasks in open environments that do not require human supervision. An example of an autonomous robot would be the Roomba vacuum cleaner, which uses sensors to roam throughout a home freely.

Teleoperated Robots

Teleoperated robots are mechanical bots controlled by humans. These robots usually work in extreme geographical conditions, weather, circumstances, etc. Examples of teleoperated robots are the human-controlled submarines used to fix underwater pipe leaks during the BP oil spill or drones used to detect landmines on a battlefield.

Augmenting Robots

Augmenting robots either enhance current human capabilities or replace the capabilities a human may have lost. Some examples of augmenting robots are robotic prosthetic limbs or exoskeletons used to lift hefty weights.

APPLICATIONS OF ROBOTICS

- Helping fight forest fires

- Working alongside humans in manufacturing plants (known as co-bots)

- Robots that offer companionship to elderly individuals

- Surgical assistants

- Last-mile package and food order delivery

- Autonomous household robots that carry out tasks like vacuuming and mowing the grass

- Assisting with finding items and carrying them throughout warehouses

- Used during search-and-rescue missions after natural disasters

- Landmine detectors in war zones

Uses of Robots

Manufacturing

The manufacturing industry is probably the oldest and most well-known user of robots. These robots and co-bots (bots that work alongside humans) work to efficiently test and assemble products, like cars and industrial equipment. It’s estimated that there are more than three million industrial robots in use right now.

Logistics

Shipping, handling and quality control robots are becoming a must-have for most retailers and logistics companies. Because we now expect our packages arriving at blazing speeds, logistics companies employ robots in warehouses, and even on the road, to help maximize time efficiency. Right now, there are robots taking your items off the shelves, transporting them across the warehouse floor and packaging them. Additionally, a rise in last-mile robots (robots that will autonomously deliver your package to your door) ensure that you’ll have a face-to-metal-face encounter with a logistics bot in the near future.

Home

It’s not science fiction anymore. Robots can be seen all over our homes, helping with chores, reminding us of our schedules and even entertaining our kids. The most well-known example of home robots is the autonomous vacuum cleaner Roomba. Additionally, robots have now evolved to do everything from autonomously mowing grass to cleaning pools.

Travel

Is there anything more science fiction-like than autonomous vehicles? These self-driving cars are no longer just imagination. A combination of data science and robotics, self-driving vehicles are taking the world by storm. Automakers, like Tesla, Ford, Waymo, Volkswagen and BMW are all working on the next wave of travel that will let us sit back, relax and enjoy the ride. Rideshare companies Uber and Lyft are also developing autonomous rideshare vehicles that don’t require humans to operate the vehicle.

Healthcare

Robots have made enormous strides in the healthcare industry. These mechanical marvels have use in just about every aspect of healthcare, from robot-assisted surgeries to bots that help humans recover from injury in physical therapy. Examples of robots at work in healthcare are Toyota’s healthcare assistants, which help people regain the ability to walk, and “TUG,” a robot designed to autonomously stroll throughout a hospital and deliver everything from medicines to clean linens.

Conclusion

Achieving safe Human-Robot Interaction is one of the grand challenges of robotics. It is necessary to design systems that do not harm human beings during operation. However, due to the lack of real world applications for pHRI, there was very little research on how to assess, rate, and improve the safety of robots for tasks with direct human contact. Mostly, the term safe was used to label dependable robotic components, for which failure rate has to be minimized and reliability to be maximized. In this sense, the monograph gives the first large scale investigation of possible injuries a human would suffer from collisions with robots and elaborates the significant factors in this complex problem.

Are you looking training with Right Jobs?

Contact Us- Artificial Intelligence Tutorial

- RPA Tutorial

- Robotic Process Automation Career Scope

- Robotic Process Automation(RPA) Interview Questions and Answers

- How to Build a Career in AI and Machine Learning?

Related Articles

Popular Courses

- Rpa Training

11025 Learners - Automation Aanywhere Training

12022 Learners - Machine Learning Online Training

11141 Learners

- What is Dimension Reduction? | Know the techniques

- Difference between Data Lake vs Data Warehouse: A Complete Guide For Beginners with Best Practices

- What is Dimension Reduction? | Know the techniques

- What does the Yield keyword do and How to use Yield in python ? [ OverView ]

- Agile Sprint Planning | Everything You Need to Know